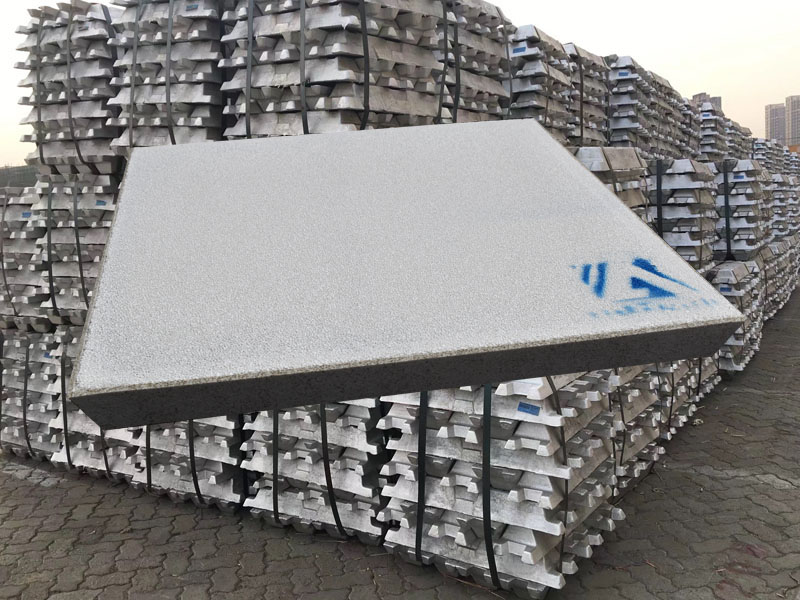

Ceramic Foam Filter Specifications

Ceramic Foam Filter Aluminium uses polyurethane foam as a carrier to fill a ceramic slurry made of refractory materials, refractory aggregates, adhesives and other fine powders and water, and then compact the slurry.

Ceramic material around the foam fiber.

After drying, curing, and tempering at high temperatures, the polyurethane is thermally decomposed, leaving behind foam ceramic products, namely ceramic floor filters.

The ceramic material used to filter molten metal has a high melting point and will not melt during the casting process, nor will it decompose into molten metal.

Canadian foam ceramic filter specifications

The PPI number in the front indicates the hole density of the product. If the model is 10ppi, it means that the uniformity of pores per 25.4mm length is 8-12.

The filtration mechanism of Ceramic Foam Filter Aluminium

filter

Just like a sieve, it can prevent foreign particles and aggregates larger than the pore size of the filter surface from passing through.

Filter cake

After sieving, many inclusions larger than the filter hole are trapped at the end of the filter inlet.

As the number of trapped inclusions increases, a large inclusion cake is formed on the surface of the inlet end of the filter.

The “filter cake” thins the liquid and makes the components smaller than the filter pore size sticks to the “filter cake” to a certain extent.

Deep bed filtration

Inside the ceramic foam filter, the flow path of the melt is tortuous, even in a small local area, there is a cross-flow phenomenon. This mainly plays two roles:

1. The possibility of particles coming into contact with the filter.

2. Change the flow rate and flow direction of the melt faster, so that the fine components in the melt are impacted and intercepted by the slag filter, straight holes (sieving), foam ceramic filter, filter cake left in the corner, and deep filtration. Slag-blocking substrate (screening) ceramic foam filter

I’s aluminum ingot production increased by 23% year-on-year in 7 months

aluminum ingot production has increased by 23% in the first seven months of the current Iian calendar year (March 21 to October 22). Compared with the same period last year, I’s Mining and Mining Industry Development and Reform Organization (IMIDRO) announced.

The country’s seven-month aluminum ingot production was 305,101 tons, compared with 247,335 tons in the same period last year.

As previously announced by the Iian Mining and Mining Industry Development and Reform Organization, compared with the previous year’s figures, I’s aluminum ingot production increased by 61% during the previous Iian calendar year 1399 (as of March 20).

Last year, the national aluminum ingot output was 446,800 tons.

In I’s the calendar year 1398, I’s major aluminum producers successfully produced 278,318 tons of products.

Compared with the previous year’s figures, the country’s aluminum ingot production in I in 1398 fell by 8%.

According to data from I’s Mining and Mining Industry Development and Reform Organization, among the country’s largest producers, I Aluminum Corporation produced 185,000 tons of aluminum ingots last year, the best performance.

In the last month of the previous year (February 19 to March 20), the national aluminum ingot production reached 41,000 tons, an increase of 38% from the 30,000 tons in the same period last year.

By the end of the current Iian calendar year (March 20, 2022), the country’s annual aluminum ingot production is planned to increase by 63%.

Last year, at the inauguration of I’s largest aluminum production complex (located in the central part of Fars Province), the former Minister of Industry stated that the country’s aluminum production is expected to double as the unit is put into operation.

Officials said that the output value of I’s mining industry is about 22 billion U.S. dollars, saying that the country’s minerals are relatively self-sufficient and there are large exports every year.