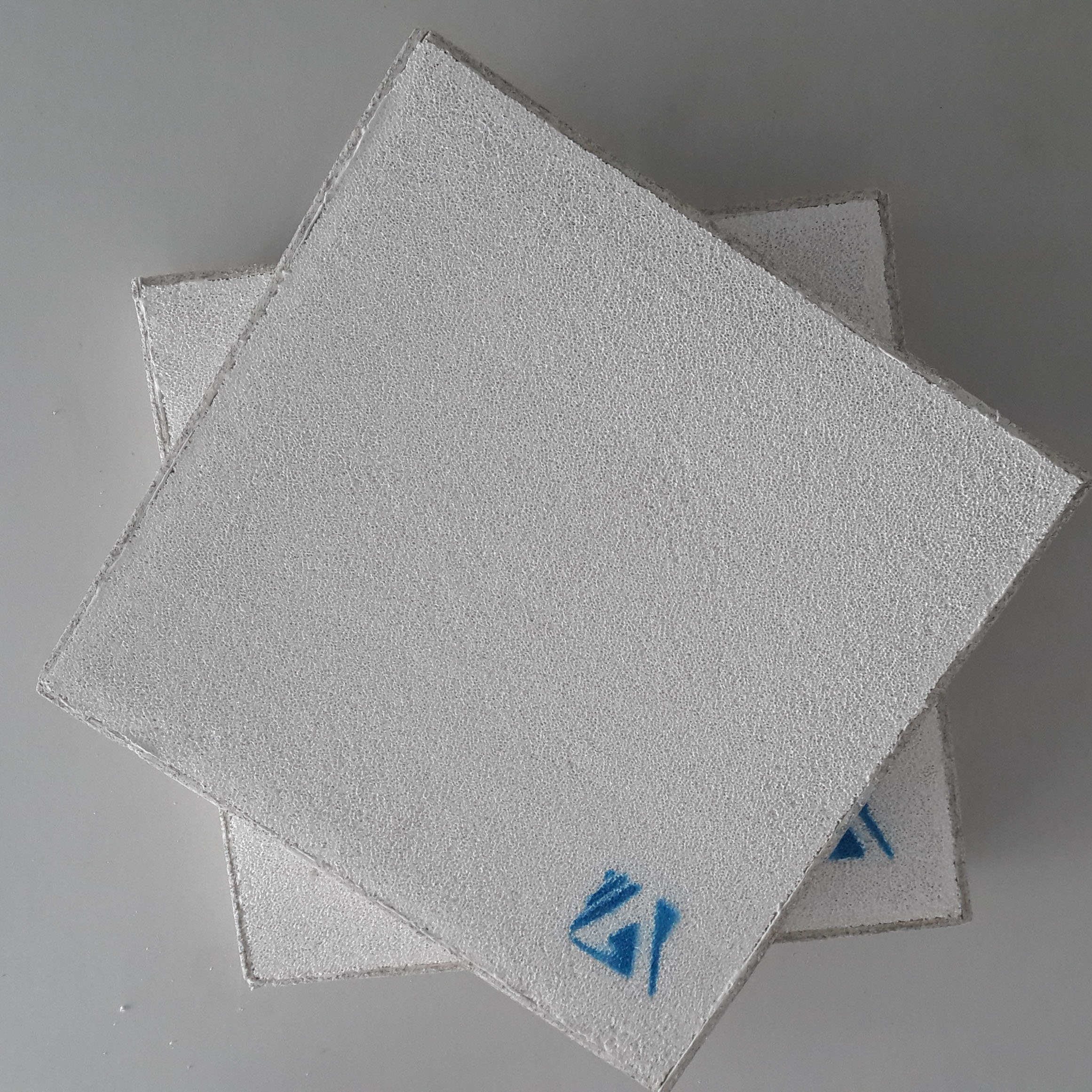

Honeycomb Ceramic Foam Filter is a domestic research fellow and employs the formulas and processes of many famous foreign companies.

The introduction of foreign advanced production equipment and some raw materials was carefully developed. Its performance fully meets or exceeds the level of similar foreign products.

Product function

It can effectively eliminate large inclusions in aluminum liquid.

A fine inclusion of a few micrometers size which is incapable of conventional processes in aluminum liquid can be removed.

Reduce the hydrogen content in the aluminum liquid.

By adsorption, the content of harmful elements (Na.k) in the aluminum liquid can be removed.

Instructions

1. Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate by hand to prevent the aluminum liquid from flowing.

3. Preheat the filter box and filter plate evenly to make it close to the temperature of the cast aluminum solution.

4. Pay attention to the change of the aluminum hydraulic head during casting. The normal starting head is 75-150 mm. When the aluminum liquid begins to pass, the pressure head will drop below 25mm, and then the pressure head will slowly increase.

5. After the filtration is finished, remove the filter plate in time and clean the filter box.

Note: Foam Ceramic filter is disposable consumables when used in the aluminum processing industry. Users are advised to carefully consider the capacity of their furnaces and select ceramic filter plates of the corresponding specifications to avoid improper use or unnecessary waste.

Honeycomb Ceramic Foam Filter

Honeycomb Ceramic Foam Filter

[…] Honeycomb Ceramic Filter can effectively remove the large inclusions in the aluminum liquid and effectively reduce the micro inclusion size of the micro inclusions, improving the surface quality and product performance. […]

[…] Ceramic Foam Filter AdTech Using three-dimensional network structure and connected pores organic foam as a carrier and immerse into thixotropic special Al2O3 molten material slurry, using four correction center distance and automatic extrusion, the slurry evenly deposited in the foam, after 1320 ℃ Drying and solidification. […]

Hi,

We are interested in your Ceramic foam filters for Aluminium casting.

Please leave your phone number or Whatsapp