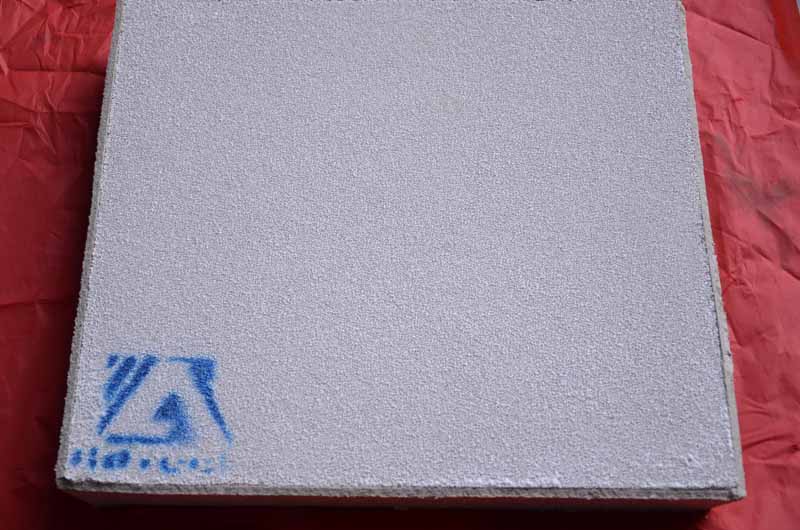

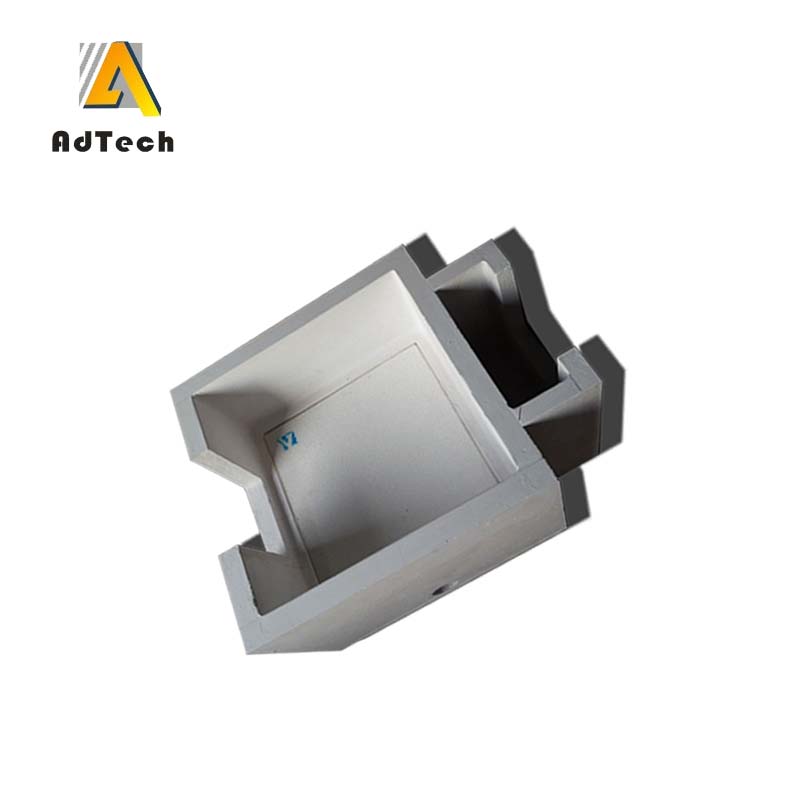

Ceramic Honeycomb Filter For Metal Filtration

Molten metal cleanliness is one of the key challenges for most casthouses.

They must produce a slab with a sufficiently low level of hydrogen, alkali metals (mainly sodium) and inclusions to make the finished product suitable for its final end use.

This is particularly important where the slab will be rolled into sheet for the manufacture of beverage cans or foil.

Molten metal cleanliness needs to be correctly managed, through a combination of having the right equipment and ensuring that it is correctly operated.

Disturbances during filtration

Whichever Ceramic Honeycomb Filter For Metal Filtration is used, care needs to be taken to ensure that the filters aren’t subject to excessive vibration or metal level changes.

These “disturbances” can cause a release of inclusions which may end up in the finished product.

Good process control downstream of the final filtration device is particularly important.

This should include careful launder preparation with special attention if any repairs are required.

Additionally, casthouse operators should be careful to minimse turbulence in certain areas, such as around the metal distribution bags.

An input of very dirty metal will overwhelm even the best Ceramic Honeycomb Filter For Metal Filtration.

Therefore, the importance of correctly conditioning the metal prior to filtration cannot be overstated.

The cleaner the metal entering the filter, the finer the filters that can then be used, resulting in “even cleaner” metal exiting the filter.

If you need further information or support to achieve good molten metal cleanliness, please do not hesitate to contact one of our Casthouse Experts(sales@adtechamm.com). We can assist you to optimise your process to meet your metal quality requirements.