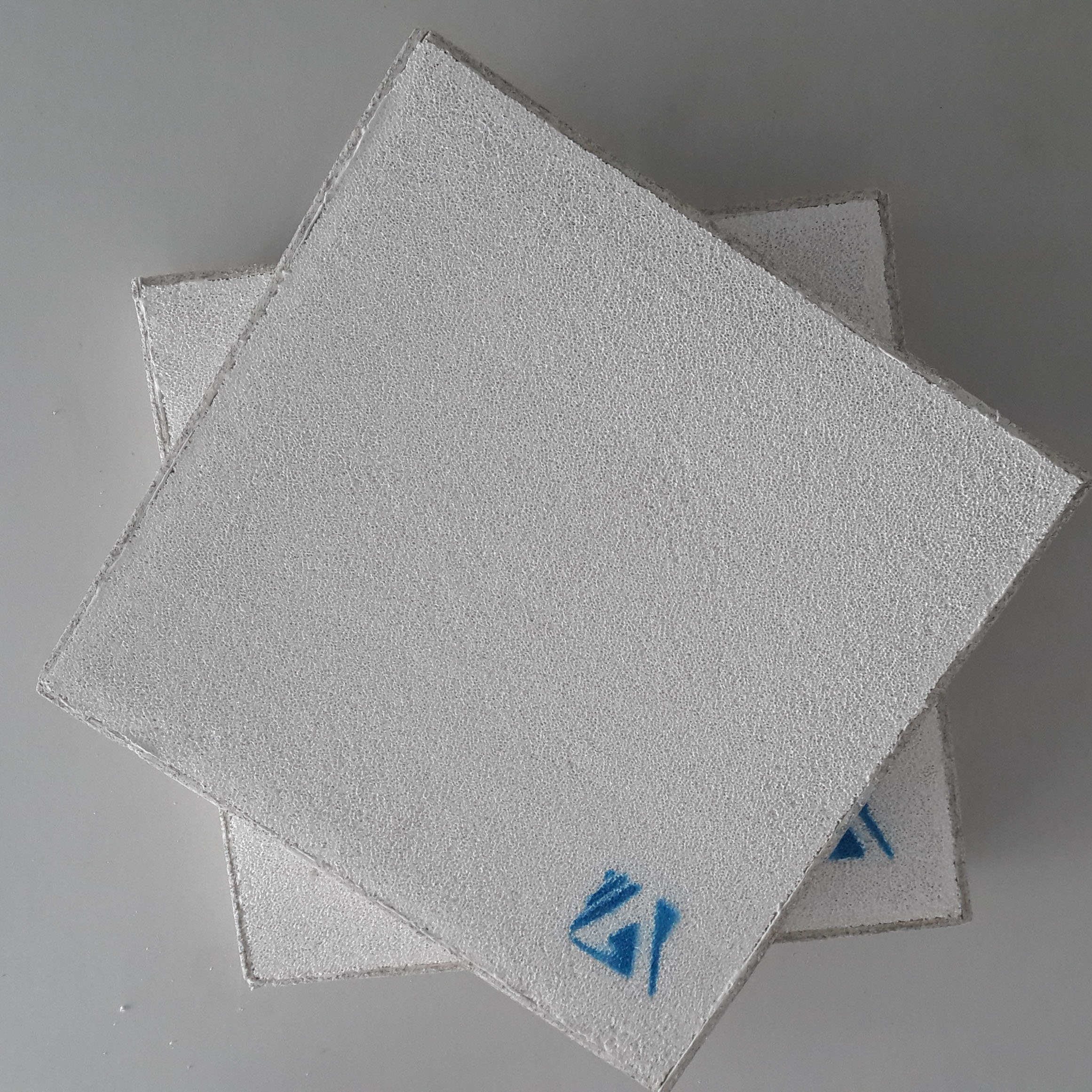

Ceramic Filter Plate

A general term for aluminum-based alloys based on aluminum.

The main alloying elements are copper, silicon, magnesium, zinc and manganese. The secondary alloying elements are nickel, iron, titanium, chromium and lithium.

The aluminum alloy has low density, but high strength, close to or exceeds high-quality steel, good plasticity, can be processed into various profiles, has excellent electrical conductivity, thermal conductivity and corrosion resistance. It is widely used in industry and is used second only to steel.

Aluminum alloy is a kind of non-ferrous metal structural material widely used in industry, in aviation, aerospace, automobile, machinery manufacturing, shipbuilding.

Smelting and casting of aluminum alloys is the main link in casting production.

Strictly control the whole process of smelting and casting, and play an important role in preventing casting defects such as pinholes, inclusions, under-casting, cracks, pores and shrinkage.

Since the aluminum melt has a large tendency to absorb hydrogen, has a strong oxidizing ability, and is easy to dissolve iron, it is necessary to take simple and cautious precautions in the smelting and casting process to obtain a high-quality casting.

Characteristics of Ceramic Filter Plate

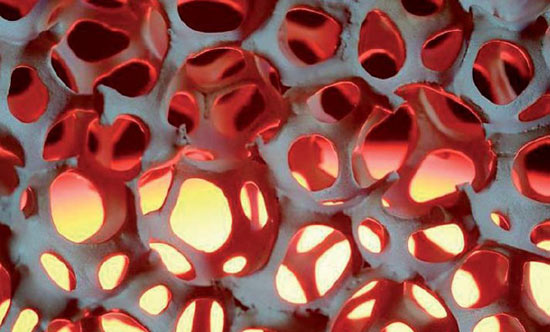

Ceramic Foam Filter can effectively remove large inclusions in aluminum fluid and adsorb fine inclusions particles of micron size, which plays a role in improving surface quality, product performance and microstructure, and improving yield. It is widely used in the production fields of aluminum profile, aluminum foil and aluminum alloy.

Ceramic Filter Plate production process

Ceramic Foam Filter adopts organic Foam Foam with three-dimensional mesh structure and connected pores as carrier to invade into special Ceramic slurry with thixotropy.

Special roller extrusion process is adopted to evenly spread Ceramic slurry onto the framework of the carrier, which is then baked and cured at high temperature.

Ceramic Filter Plate method of use

1.Clean the filter box.

2. Gently put the filter plate into the filter box and press the sealing gasket around the filter plate with your hands to prevent the side flow of liquid aluminum.

3. Uniformly preheat the filter box and filter plate to make it close to the temperature of liquid aluminum. Preheat to remove moisture and facilitate initial instantaneous filtration. Preheating may be done by electric or gas heating. Normally, it takes about 15-30 minutes.

4. when casting attention to observe changes in aluminum hydraulic head, normal starting pressure head is 100-150 mm. When aluminum begins through, pressure head will drop to 75-100 mm less, then pressure head will slowly increase.

5. During the normal filtration process, avoid knocking or vibration on the filtration plate. Meanwhile, the flow trough should be filled with aluminum-water to avoid too large disturbance of aluminum-water.

6. Take out the filter plate and clean the filter box after the filtration.

Ceramic Filter Plate light transmittance

Light transmittance refers to the effective filtration area of ceramic foam filter plate.

The higher the light transmittance is, the fewer the blind holes are, and the more effective filtering holes.

The foam ceramic filter plate to be tested is placed on the light box with built-in 200W incandescent bulb, and the transparent square plastic plate with uniform cloth 5.0×5.0mm square is used to measure the light transmittance of the large surface of the filter plate.

So as to calculate the light transmittance of the tested filter plate.

In this standard, the light transmittance (through-hole rate) of the filter plate shall be more than 95%.

[…] of the total volume of the cavities in the filter plate product to the total volume of the Ceramic Filter Plate product. Porosity determines the filtration capacity of the foam ceramic filter plate per unit […]

[…] the aluminum filter box, keep it clean and intact. 2.Put the ceramic foam filter into filter box carefully , press Sealing […]

[…] Foundry Filters Instructionsc 1.Clean the Casting filter box. 2.Gently put the filter plate into the casting filter box and press the sealing gasket around the filter plate by hand to prevent […]

[…] general, the selection of the ceramic filter plate should take into account factors such as the quality of the finished product, the flow rate of the […]

[…] Aluminium Billet (M) SDN BHD said that the commonly used ceramic filter plate specifications are: 7in, 9in, 12in, 15in, 17in, 20in, 23in, 26in or customized according to […]

[…] we introduce the use of ceramic filter plates Check and clean the surface of the filter box to keep the filter box clean and free of […]

[…] adsorbed particles in the pores of the filter plate continue to gather, so that the pores of the ceramic filter plate become smaller and the filtering effect is improved. . But when the amount of impurities adsorbed […]

[…] up the rubbish on the surface of the box to keep the box clean and free from damage. Place the ceramic filter plate gently on the filter box, and manually press the sealing gasket on the filter plate to prevent the […]

[…] plate to make it close to the temperature of the molten aluminum. The preheating temperature of the ceramic filter plate is above 260°C. Preheating to remove the adsorbed water can temporarily open the holes of the […]

[…] them, the simplest filtration method is glass cloth filtration, preferably foam ceramic filter plate, filter tube, deep bed filtration, etc. Glass cloth filtering aluminum melt has been widely used in […]

[…] gradually decreases, the permeability decreases, and the filtration The accuracy is improved. The ceramic filter plate filters […]

[…] aluminum alloy profile manufacturers, the advantages of using ceramic microporous ceramic filter plate to purify aluminum 1. Improve extrusion efficiency When using the filter plate to purify the 6063 […]

[…] put the ceramic foam filter plate into the filter box. Then press the gasket around the filter plate by hand. Prevent lateral flow of molten aluminum. Preheat the filter box and filter plate evenly. […]

[…] box. 2. Gently insert the ceramic filter plate into the filter box, and press the gasket around the ceramic filter plate by hand to prevent the aluminum liquid from flowing out. 3. Preheat the filter box and the filter […]