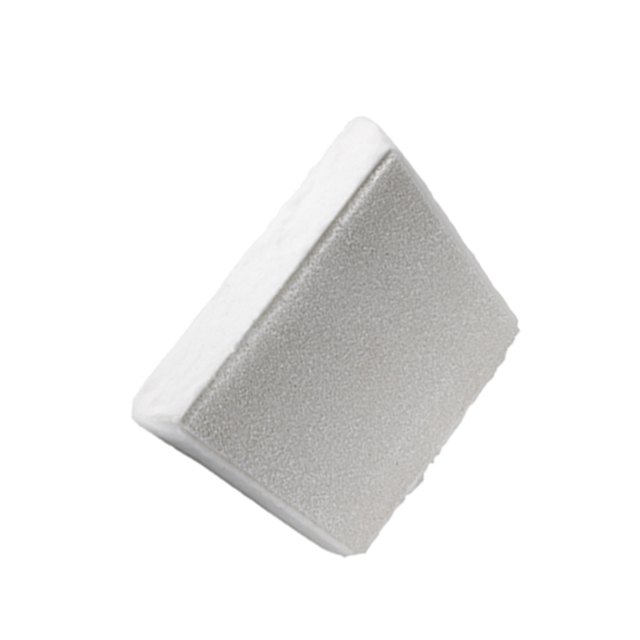

Aluminium Spain Casting Filter is used for the filtration of molten aluminum, surface filtration and internal filtration.

Surface filtration means that solid impurities are mainly deposited on the surface of the filter medium.

Internal filtration means that the inclusions of the aluminum liquid flow along the tortuous channels and the pores in the filter medium, and are directly intercepted and absorbed.

With the progress of filtration, the effect of sedimentation, adhesion to the pore wall and firm adhesion to the pore wall, as the filtration proceeds, the effective filter cross section of the channel gradually decreases, the permeability decreases, and the filtration The accuracy is improved. The ceramic filter plate filters internally.

Aluminum alloy processing plants have adopted advanced aluminum purification filter boxes, mainly ceramic plate filter devices, deep bed filter devices and filter box devices. Since the first successful research of ceramic foam filters for aluminum alloys in the 1970s, ceramic foam filters have developed rapidly and are currently the most widely used in aluminum processing plants.

Aluminium Spain recommends Adtech Casting Filter and filter box, and recommends the email sales@adtechamm.com to other aluminum casting plants in Spain.

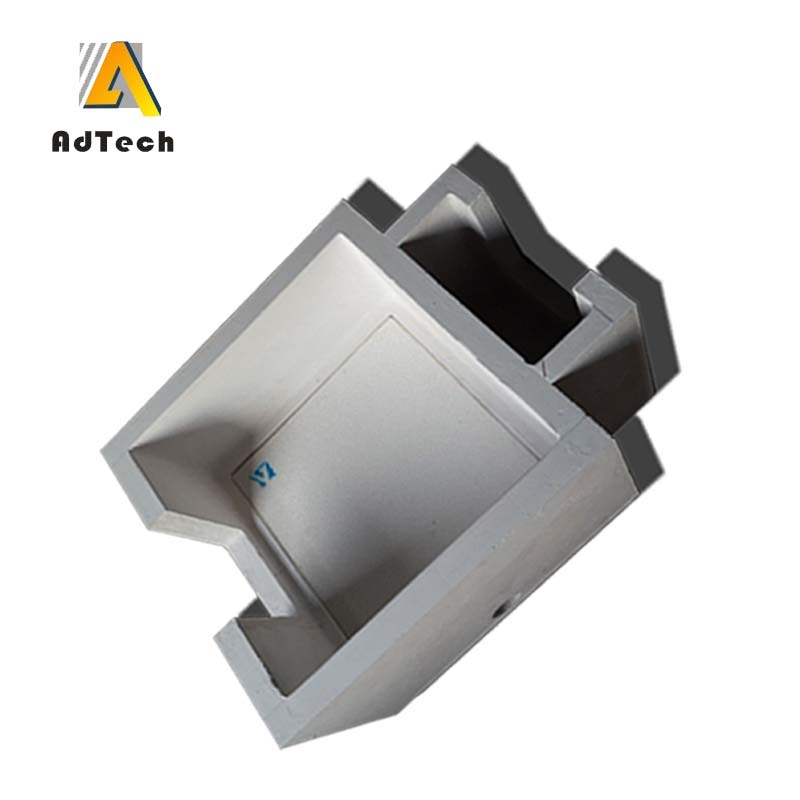

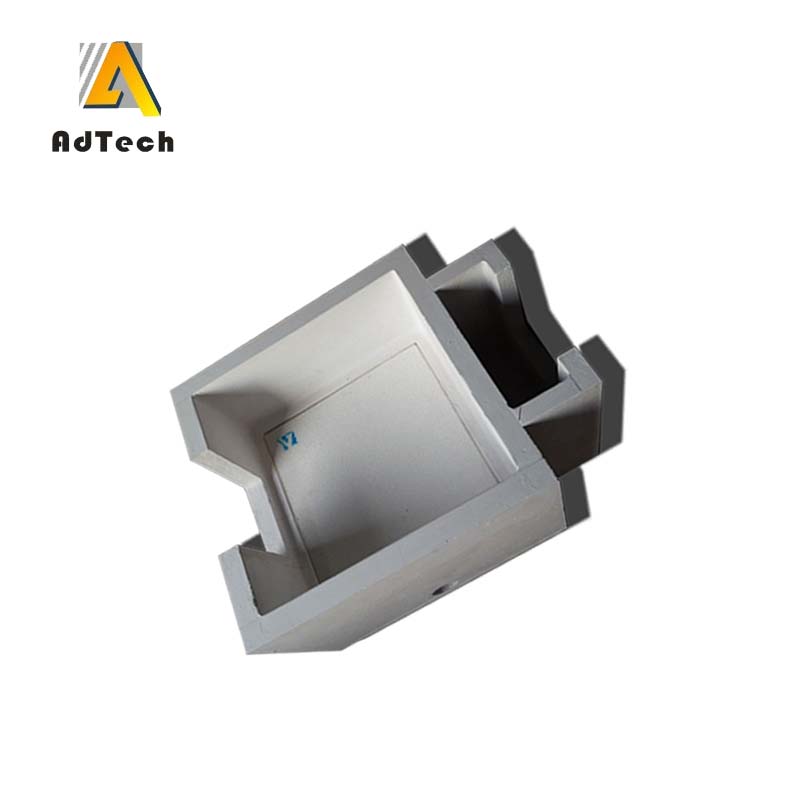

Aluminum purification filter box

In order to save production costs, Aluminium Spain uses aluminum purification filter boxes for casting ingots for extrusion or extrusion as general products. Aluminum purification filter boxes have been widely used at home and abroad. The deep bed filter equipment is mainly aluminum foil and PS version. When supplying raw materials such as cans and aviation materials, filtering devices are introduced

The aluminum purification filter box absorbs the cylindrical and heat exchange technology of the chemical industry. After being applied to the aluminum casting industry, when the flow of liquid metal is constant, a large number of tube components increase the filtering area and improve the filtering efficiency. It mainly meets the quality requirements of high-precision products such as airplanes, automobiles, magnetic disks, aluminum foil and cans.

Molten Aluminium Removal Technology

The existing aluminum water removal filter box production line on the market, in the remelting aluminum ingot smelting process, mostly from the melting furnace through the flow tank directly into the casting package, or in the flow tank between the casting package Filter box, but this technology has defects. In the casting process, all the aluminum liquid must be discharged due to temporary parking.

Otherwise, the Aluminium Spain Casting Filter will be solidified in the filter plate in the filter box, which will cause the filter plate to be scrapped. The new filter plate causes waste of working hours and increases production costs.

In response to this process defect, my engineering and technical personnel, after years of process improvement and practice.

Specialty Custom Molten Aluminium Filter Box is to protect the filter plate by providing a partition dam plate in the filter device.

At the same time, according to the buoyancy principle in physics, it also plays a purifying role.

This technology is used in conjunction with the aluminum liquid purification device applied by our company.

The purpose is to achieve the final purification of aluminum liquid through the combination of two sets of devices to realize the aluminum wire rod.