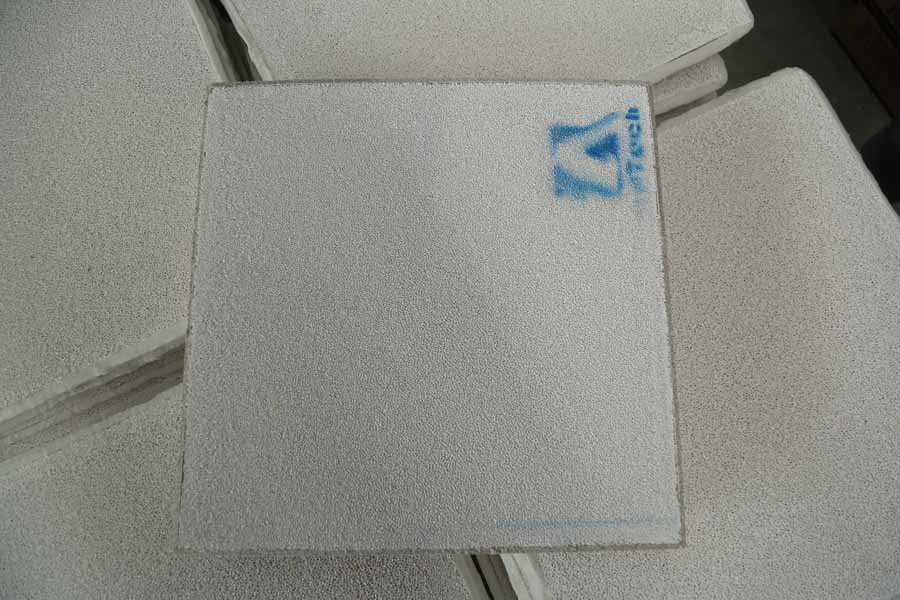

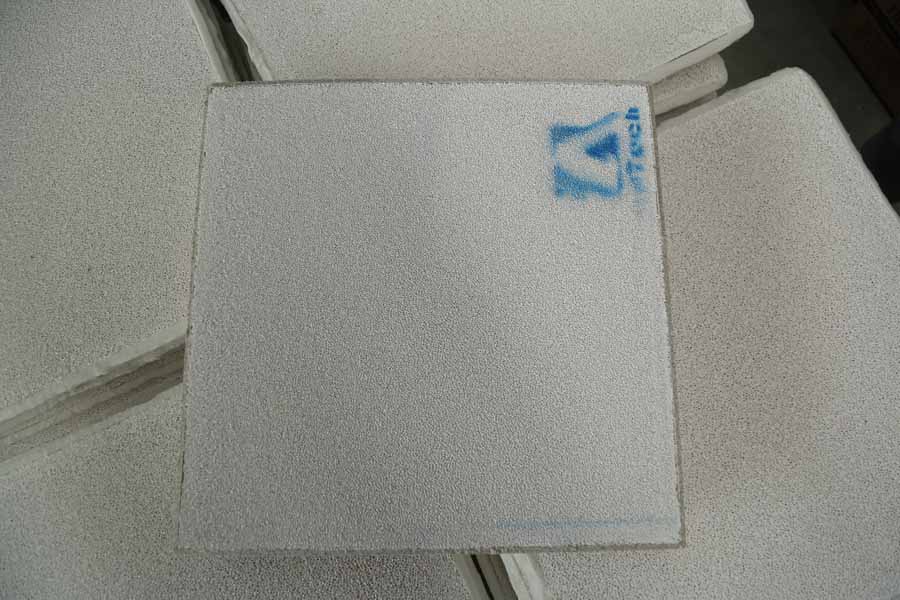

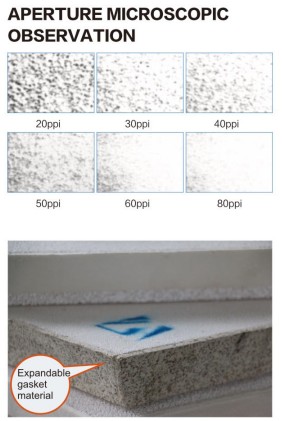

Sell Foundry Filter adopts a three-dimensional mesh structure, connects the pores of organic foam as the carrier, and penetrates into the thixotropic alumina paste. The four-square compensation intermediate spacing automatic extrusion technology is adopted. The paste is evenly coated on the foam skeleton of the carrier at 1180°C

Installed on the filter tank, used for the filtration of aluminum alloy liquid impurities to meet the needs of aluminum alloy precision casting with high added value and high technical performance for aviation and transportation. For example, products such as computer hard disks, printed PS substrates, manufacturable materials, and fan blades of jet turbine engines.

The basic structure of the ceramic filter: The ceramic filter is composed of a plate base, a positioning table, a blowing outlet and a surface film. Sell Foundry Filter – sales@adtechamm.com

There are crisscross capillary holes (about 1~10μm in diameter) inside the Foundry Filte. This is the filtrate channel. This component is called the panel base. 2. The composition of the ceramic filter is silicon carbide, corundum and other materials. The main components of the outlet of the ceramic filter and the positioning base are made of stainless steel or polymer materials.

The main features of Adtech Sell Foundry Filter which has are as follows

1. Filtration accuracy includes microfiltration, microfiltration, ultrafiltration, nanofiltration, reverse osmosis, with good effect

2. High mechanical strength, stable chemical performance, good wear resistance, low electrical resistance, strong anti-blocking, easy to loosen and clean

3. High efficiency, high output, neatly arranged screen holes, uniform and neat.

Advantages of ceramic filters

1. By adopting the principle of adsorption, large inclusions in molten aluminum can be effectively removed, and small inclusions of small size can be effectively adsorbed

2. No slag falling, effectively reducing the pollution of molten aluminum

3. Improved good thermal shock resistance and resistance to molten metal corrosion

4. Automatic production line, 3 calibration procedures, accurate size, more in line with the filter box

5. Improve surface quality, improve product performance, and improve microstructure.

Effectively remove large impurities in molten aluminum, adsorb micron-sized particles, improve surface quality, improve product performance, improve microstructure, and increase output. It is widely used in aluminum, aluminum foil, aluminum alloy and other production fields. Sell Foundry Filter – sales@adtechamm.com

Instructions for use of ceramic filters

Check and clean up the rubbish on the surface of the box to keep the box clean and free from damage.

Place the ceramic filter plate gently on the filter box, and manually press the sealing gasket on the filter plate to prevent the flow and floating of the aluminum liquid.

Evenly preheat the filter element and the filter plate to make it close to the temperature of the molten aluminum. The preheating temperature of the filter plate is above 260°C. Preheating to remove the adsorbed water can temporarily open the holes of the initial filter to prevent heat from rising and shrinking, blocking part of the holes of the filter plate. The preheating can be electric heating or gas heating, usually for 15-30 minutes.

During casting, observe the changes of the aluminum hydraulic head to maintain the normal requirements for the flow control of the molten aluminum.

The normal initial pressure head is 100-150mm. When the liquid starts to pass, the pressure head drops below 75-100mm, and the pressure head slowly increases.

During the normal filtering process, do not knock or vibrate the filter plate. In addition, in order to avoid interference caused by too large or too small molten aluminum, please fill the water tank with molten aluminum.

After filtering, please remove the filter plate immediately and clean the filter box.