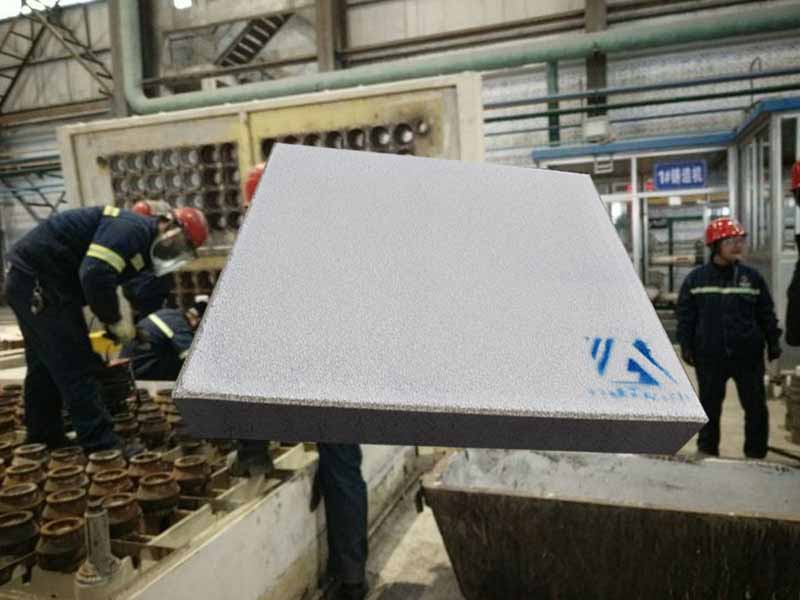

Molten Aluminum ceramic foam filter Century Extrusion is installed on the CFF box machine to filter liquid impurities in the aluminum alloy to meet the production of aluminum alloy precision castings with high added value and high technical performance for aviation and transportation.

The filtration purification method is to filter impurities, gases and some harmful elements in the molten aluminum through a filter (main body) in the process of casting salt or casting.

The principle is adsorption filtration and mechanical filtration.

The mechanical properties of aluminum alloy filter castings can be greatly improved, and the strength, toughness and elongation can be improved.

After the molten aluminum is sieved, the quality of ingots and castings is also greatly improved.

There are many lead melt filtering materials, such as glass cloth, refractory fiber mesh, magnesium fluoride, calcium fluoride and so on.

For Asian casting filter agents, please contact the Chinese manufacturer sales@adtechamm.com

In the process of ceramic foam filters for aluminum smelting and casting, the purity of the aluminum melt is related to the metallurgical quality of the ingot.

The most common filtering method is to use a filter plate to filter out impurities in the molten aluminum. Generally, the cast filter is directly placed in the filter box for production filtration.

Liquid aluminum filter box is an auxiliary equipment that can improve this situation. We put the filter plate in the liquid aluminum filter box. The molten aluminum is repeatedly filtered through the multi-layer filter plate, which greatly improves the metallurgical properties of the ingot. quality.

Inclusions and gases in the metal will seriously affect the strength, fatigue resistance, corrosion resistance and stress corrosion cracking performance of the material.

Effectively controlling the oxidized inclusions in the melt and improving the quality of cast rods and rolled plates have become a common goal pursued by the metallurgy, casting, and materials industries of various countries.

The 30ppi ceramic filter can remove most of the inclusions in the cast aluminum alloy melt.

Aluminum and its alloys are prone to oxidation and gas absorption during the smelting and casting process, and defects such as inclusions and pores are easily formed during the die-casting process, which is not conducive to the alloy structure and causes the mechanical properties to decrease. The corrosion resistance of the alloy. And reduce output.

Therefore, proper control of the smelting process and improvement of the quality of the aluminum melt are the key to improving the quality of aluminum die castings.