Ceramic Foam Filtration

Ceramic Foam Filtration in continuous or batch casting applications. Available as a single or double design, these units offer adjustable height for leveling, tap out systems to enable drainage, and filter box cover systems. The radiant tube heater system can pre-heat the empty box or holding the box with metal. An optional PLC control unit is available to control pre-heat, filter box cover system and clam.

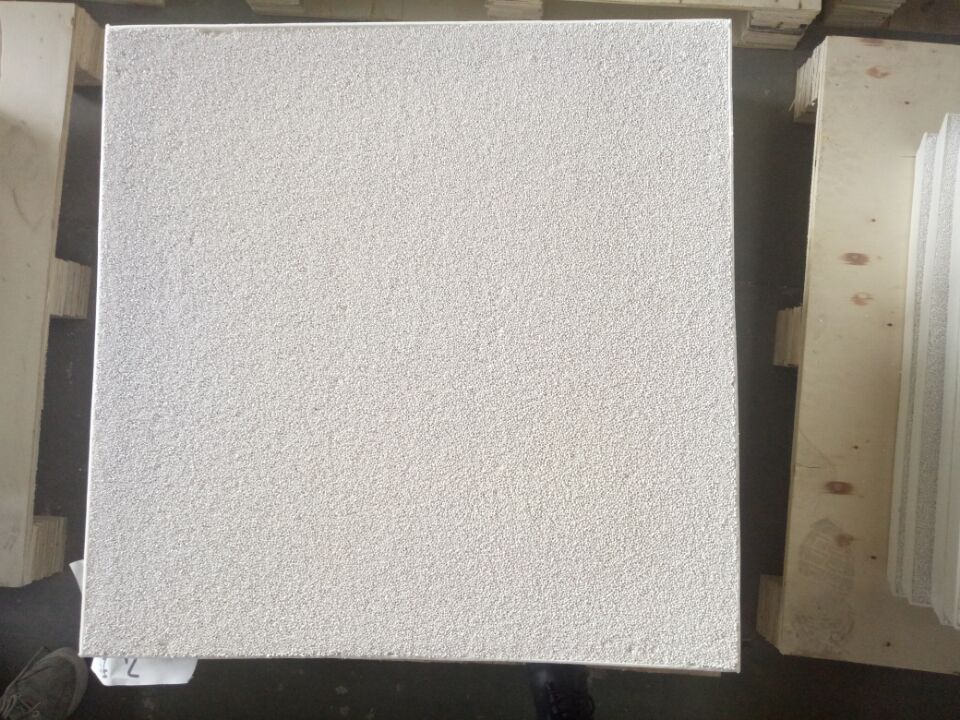

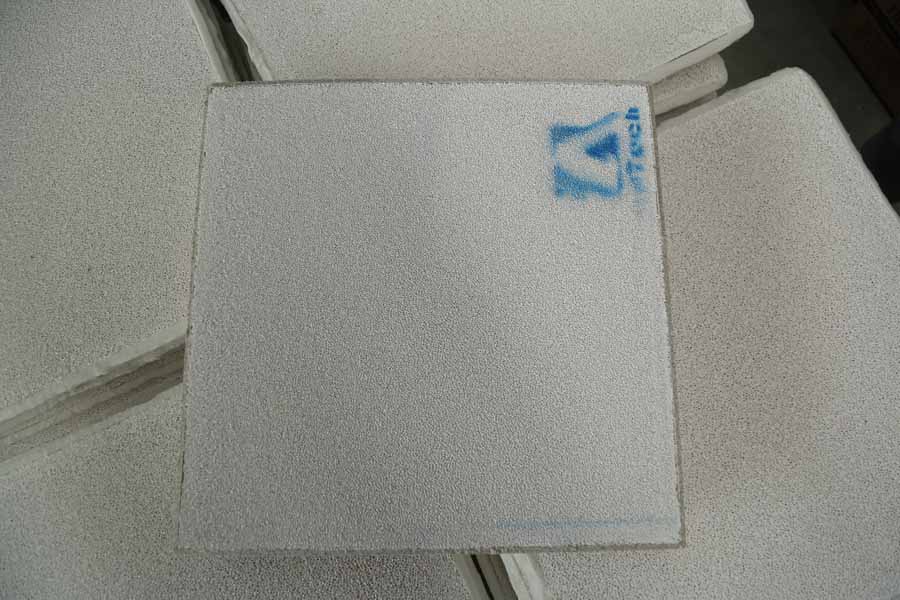

Adtech ceramic foam filters provide a cost effective and proven method to remove inclusions from aluminum melts. The exact removal efficiencies can vary greatly depending on application conditions. Typically, efficiency increases as filter cell size and the velocity of the metal in the filter decrease.

Ceramic Foam Filtration Advantages

A complete turnkey filter box system

Supplied to the exact requirements of the customer

Available with or without a heating system

Variable operating height for ease of use and connection to existing launder system

“Tile-saving technology” is popular within casthouse application. With this kind of design, usually, one tile can be used up to six casts.

Adtech Ceramic Foam Filtration with its characteristics of light-weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, erode resistance, high-performance, competitively priced, is designed for filtering impurities from liquid metals. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less. And the cast quality becomes much better.

Ceramic Foam Filtration also can be called Extruded Ceramic Filter, are widely used as molten metal filtration in metallurgical and foundry industries. This product has the characters of excellent resistance to thermal shock, high strength, high porosity and specific surface area. With its unique straight channel honeycomb designs, it can increase the specific surface area between molten metal and ceramic filter, thereby to improve its adsorpting and capturing tiny impurities ability, so as to get ride of non-metal impurity and gas, make the metal liquid steady, purify metal liquid. It can not only reduce casting cost, but also improve casting quality. Materials in Cordierite, Mullite, and Alundum Mullite.