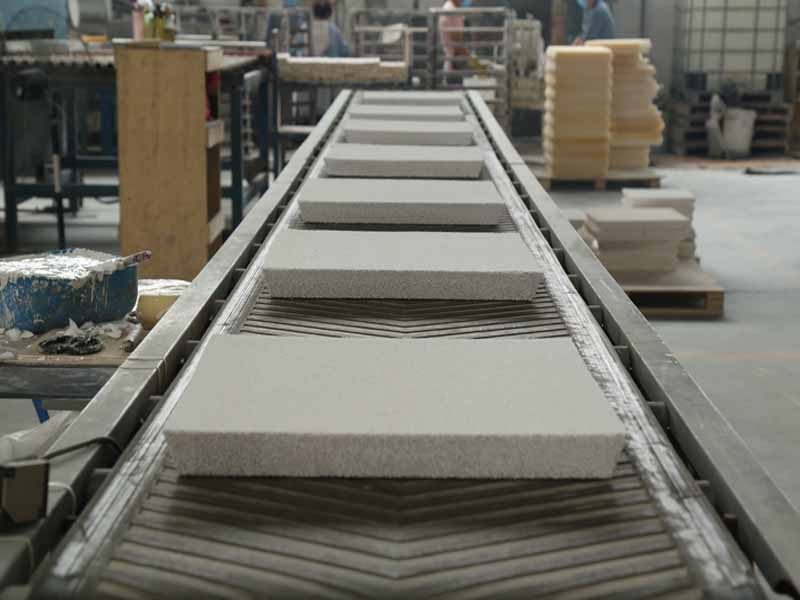

Brazil Aluminum liquid filtration plays a very important role in the aluminum liquid purification system.

The ceramic filter plate can effectively remove the large inclusions in the molten aluminum, and effectively reduce the size of the micro inclusions, and improve the surface quality and product performance.

Improve the effect of microstructure and increase yield. As long as it is used for precision casting of aluminum alloy in aviation and transportation.

The advantages of Brazil Aluminum liquid filtration include

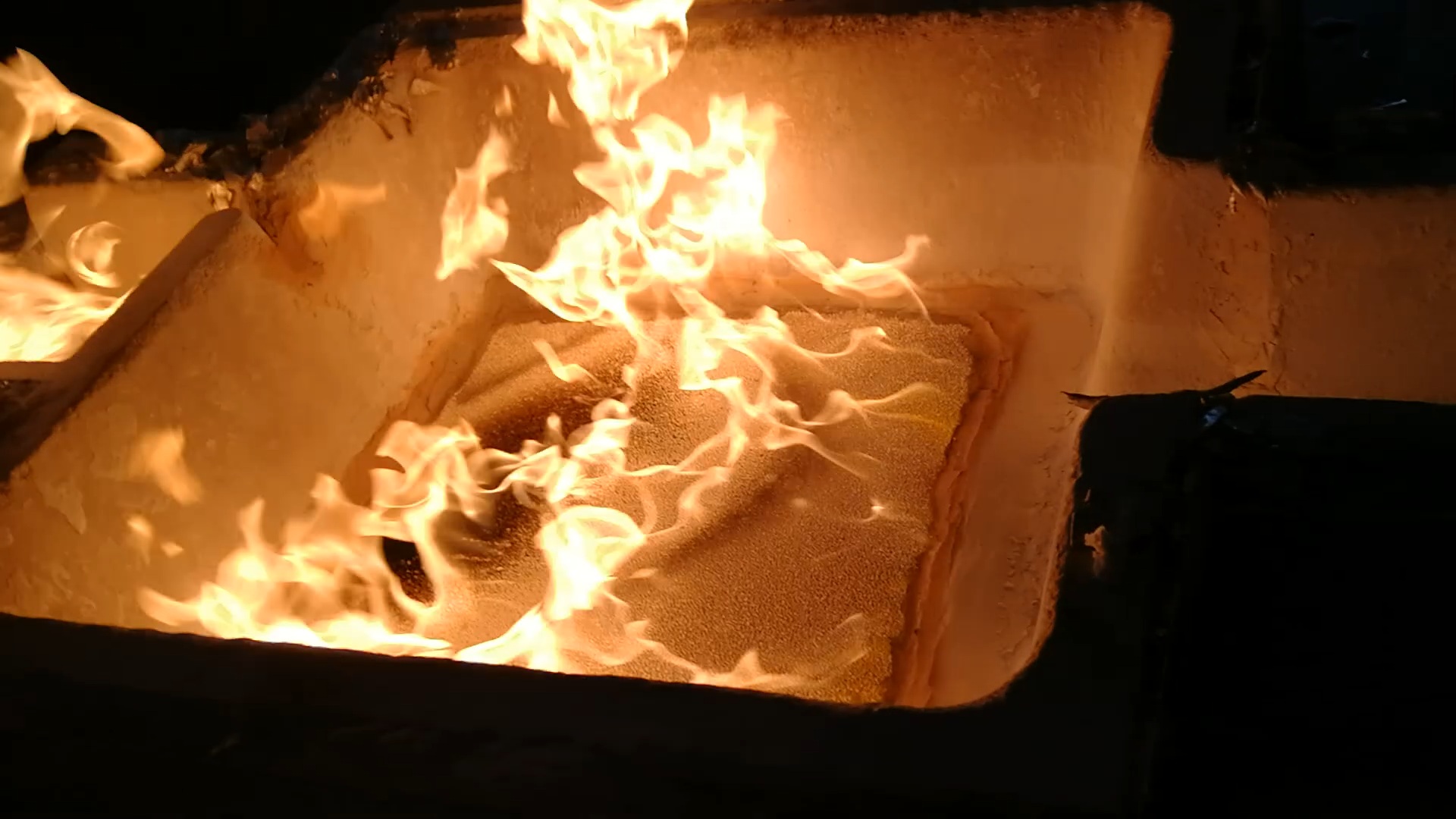

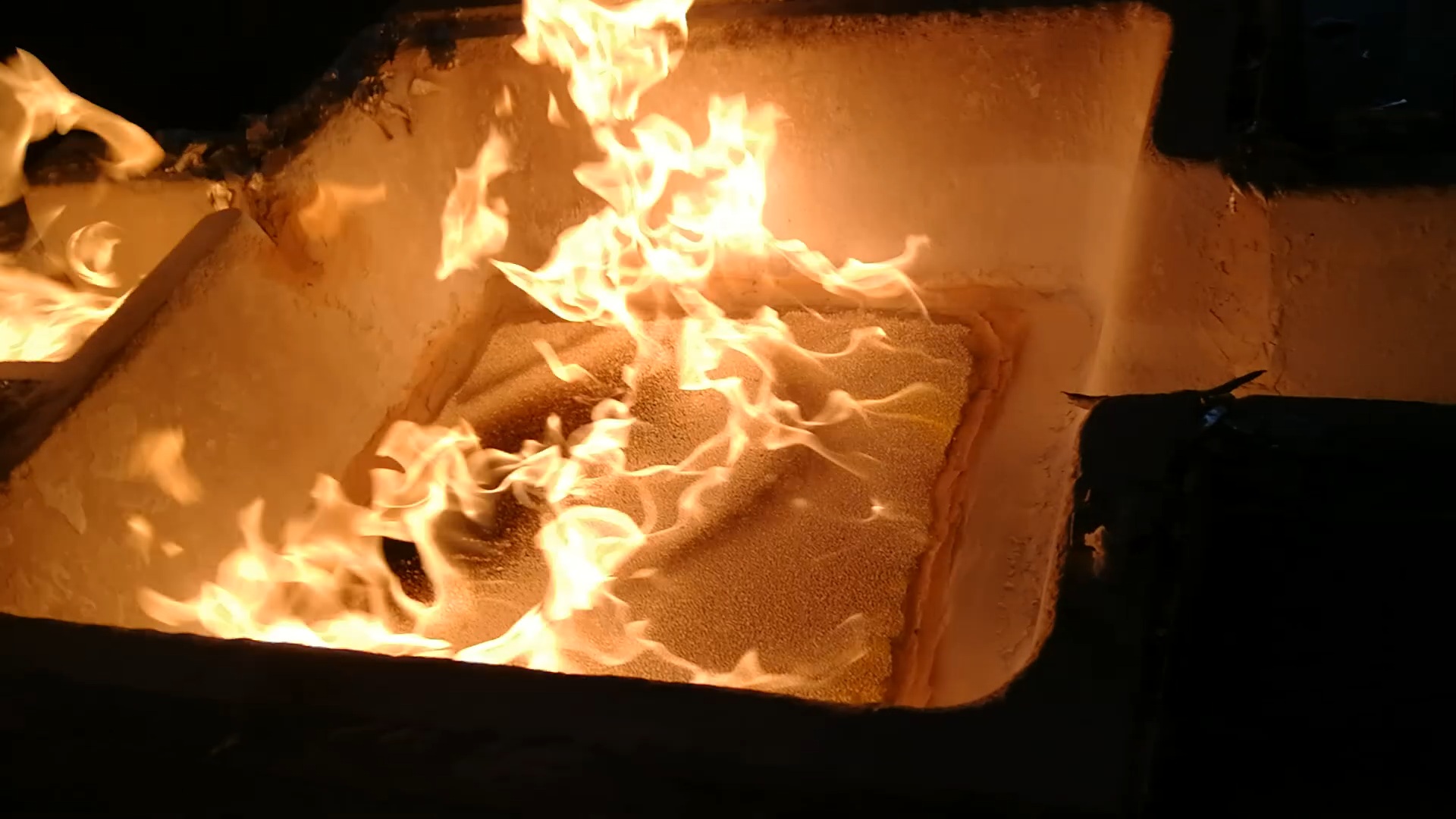

1. Reduce the gas and inclusions contained in the casting, reduce the turbulence of the molten metal when filling the mold, and reduce the surface defects in the casting.

2. Significantly reduce the rejection rate of castings, increase the compression and sealing properties of the castings, and increase the elongation and tensile strength of the castings.

3. Improve the surface finish of castings, improve the fluidity of molten metal, and increase the filling capacity and feeding capacity of the melt.

4. Reduce processing time and tool wear and improve the surface quality of castings.

Brazil Aluminum summarizes the following characteristics of Aluminum liquid filtration during use

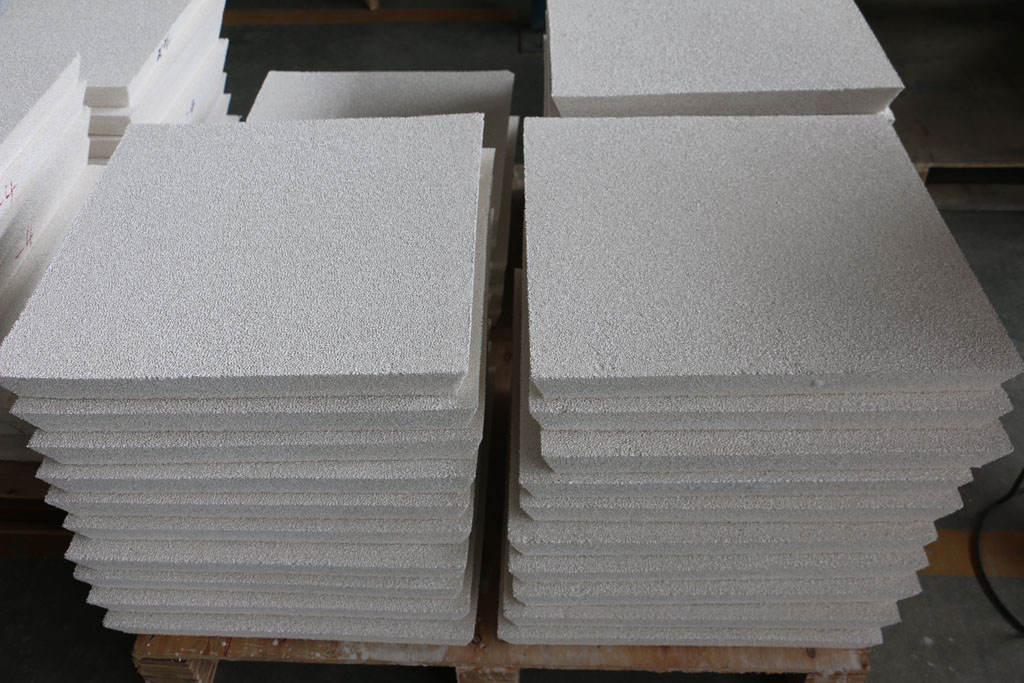

1. Ceramic foam has high mechanical strength, chemical stability, high thermal shock resistance and liquid metal flow shock resistance even in high temperature environments.

2. There is no slag or broken during processing to ensure the quality of molten metal and stable chemical composition.

3. With a large and stable metal flow, even if the molten metal contains high inclusions, it will not block the ceramic foam filter.

Brazil Aluminum is recommending the purchase email of ceramic foam filter sales@adtechamm.com to aluminum foundries in South America.

Brazil Aluminum liquid filtration can effectively remove and absorb various impurities in molten aluminum, improve surface quality, product performance and microstructure effectiveness.

Brazil Aluminum chooses different filtering precisions during the use of ceramic foam filter

1. Aluminum alloy bar selection: 10-30ppi

2. Long-term casting options: 30-50ppi

3. High-quality aluminum profile or plate selection: 40 or 50ppi

4. Aluminum foil continuous casting and rolling options:> 50ppi