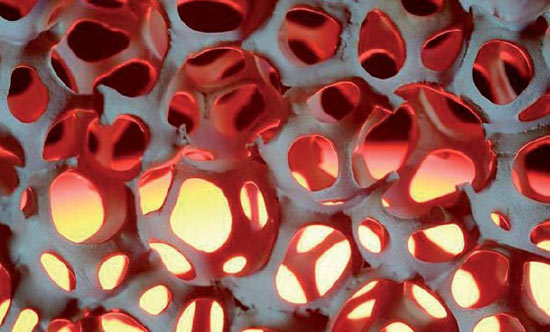

Aluminium Spain Foundry Filter captures aluminum dross from molten aluminum. This ability is important for maintaining a clean ingot during metal solidification. Therefore, the quality and productivity of downstream processes such as forging, extrusion, and rolling can be guaranteed.

Adtech is constantly exploring to ensure that customers have access to the highest technology available in the market to produce the highest quality aluminum ingots, aluminum plates, etc. Our technology guarantees the adaptability of casting quality to the most important end product applications.

Keywords=aluminum ceramic foam filter, ceramic foam filter, ceramic filter plate, porous aluminum plate, silicon carbide ceramic foam filter, alumina ceramic filter, alumina foam filter

Aluminium Spain introduced that Foundry Filter uses ceramic foam filters to provide several important advantages to improve the quality of high-quality aluminum castings.

Improved mechanical properties

Reduction of dye penetration

Reduction of non-metallic X-ray evidence

Reduce rework/scrap

Improvement of processing characteristics

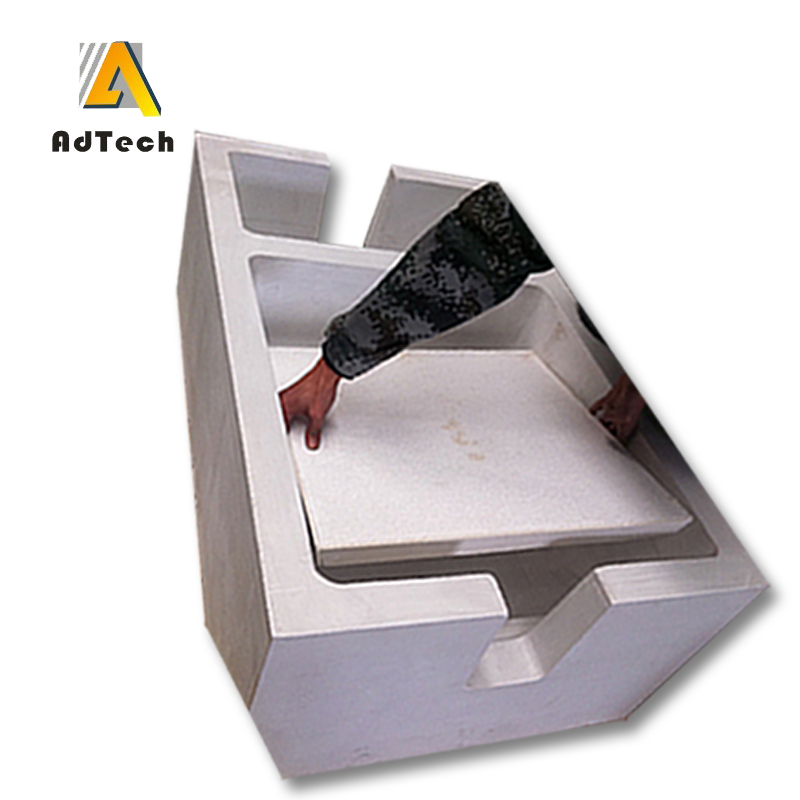

Ceramic foam filter Dimention

660x660x50(26″)

584x584x50(23″)

508x508x50(20″)

432x432x50(17″)

381x381x50(15″)

305x305x50(12″)

228x228x50(9″)

178x178x50(7″)

Ceramic foam fitler Pore Size(PPI):10/20/30/40/50/60

CFF Unit with Aluminium Spain Foundry Filter has a long life of the furnace body using a new high-silicon melting manufacturing technology, mainly used for the high value-added, high-tech performance of aluminum production requires melt purification, replacing the industry’s high cost ceramic tube Filtration equipment and ordinary plate filter equipment products, using this plate filter and related technical guidance, effective filtration barrier for micro-level impurities of aluminum products produced to meet customer demand