20 Inch Ceramic Foam Filter

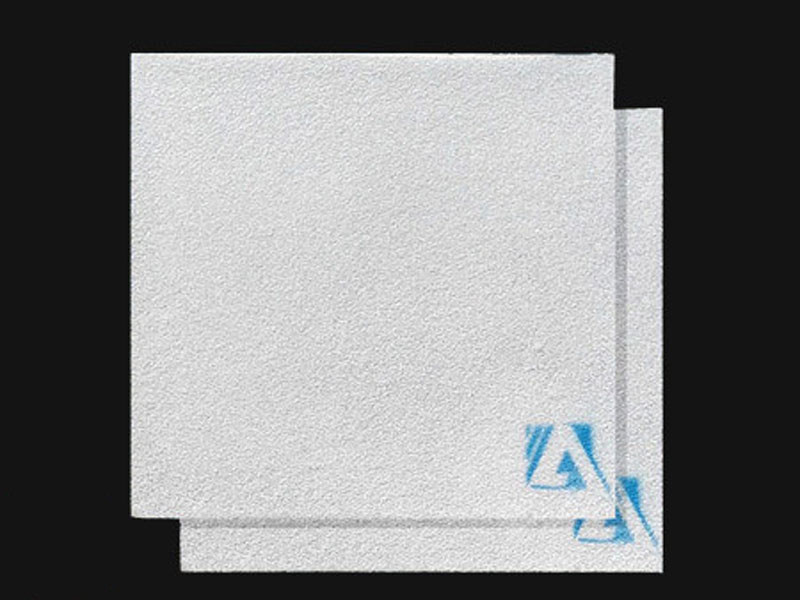

The ceramic foam filter has the advantages of high porosity, low loss of thermal shock, high mechanical strength at normal and high temperature, large specific surface, good chemical stability and excellent filtering screen functions, filtering collections of adsorption and adsorption especially for tiny impurity 1 ~ 10μm.

The three-dimensional structure can improve cast quality in a large range by changing molten metal from a swirl flow to a thin-layered flow, removing gass and smoothing the cast. Ceramic foam filter is not only applied for molten metal filtering in high temperature, but gas treatment in high temperature, catalyzer carrier, solid heat exchange and advanced filling for the chemical industry.

CERAMIC FOAM FILTERS HAVE BEEN SIMPLY DEVELOPED AS A NEW TYPE OF CAST METAL FILTER TO REDUCE THE LACK OF CASTING IN LAST YEARS. WITH ITS FEATURES OF LIGHT WEIGHT, HIGH MECHANICAL POWER, LARGE DETERMINED SURFACE AREAS, HIG

ALUMINUM CERAMIC FOAM FILTERS. PLEASE IMPROVE THE QUALITY OF ALUMINIMU ALLOY CASTING AND OTHER ALLOY ALLOY COLORED CASTING. FIX CRYSTALLOID STRUCTURE. IMPROVE THE FUNCTION OF THE MACHINE. COMMUTATED FUNCTATION.

20 Inch Ceramic Foam Filter is a modern material in demand in many industrial fields. It is made from highly dispersed mineral powders, as well as from liquid foams; has a porous structure.

The unique properties of this material make it simply indispensable in many industries. Ceramic foam material has low thermal conductivity and high heat resistance.

20 Inch Ceramic Foam Filter is used to separate molten metal from mechanical impurities. PFC is characterized by the so-called three-dimensional structure of mutually open pores. This structure allows you to maximize the filtering process.

Ceramic foam filter is in demand in the metallurgical industry, since ceramic foam has a number of unique properties.

Modern foundry is simply not possible without the use of this type of filtering.