Ceramic Foam Filters For Casting

Ceramic Foam Filters For Casting use good portiforium foam and high purity ceramic as raw material, can removes non-metal solid mixture from molten aluminium and aluminium alloy fusant effectively in your aluminium casting industry.

Advantages of Ceramic Foam Filters For Casting

even aperture, high porosity, proper sinter, high strength of anti-flexing and anti-compression, effective filtering.

Function of Ceramic Foam Filters For Casting

It is widely applied to the aluminium fusant filter equipment of continuous casting, half-continuous casting, gravity casting, and low pressure casting.

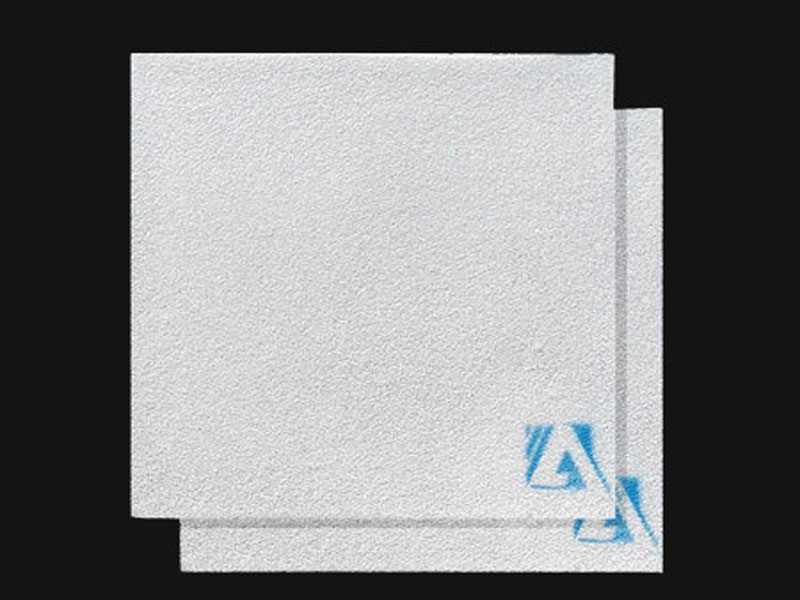

Ceramic Foam Filters For Casting are different from aperture specifications from 20 to 50ppi, with different sizes and shapes.

Ceramic Foam Filters For Casting is just developed as a new type of molten metal filters to decrease casting flaw in recent years. It is made from high quality ceramic materials, whose main components are Al2O3, Sic, ZrO2, MgO etc. Ceramic Foam Filter has the characters of light weight, high mechanical strength, large specific surface areas, high porosity, excellent thermal shock resistance, chemical corrosion resistance and high temperature stability in molten metal. With the distributing pores net structure, they are able to increase the surface areas, and absorb the sinter, the liquid metal becomes more pure, waster quality problems such as sand pore and air pore are much less and the cast quality becomes much better.

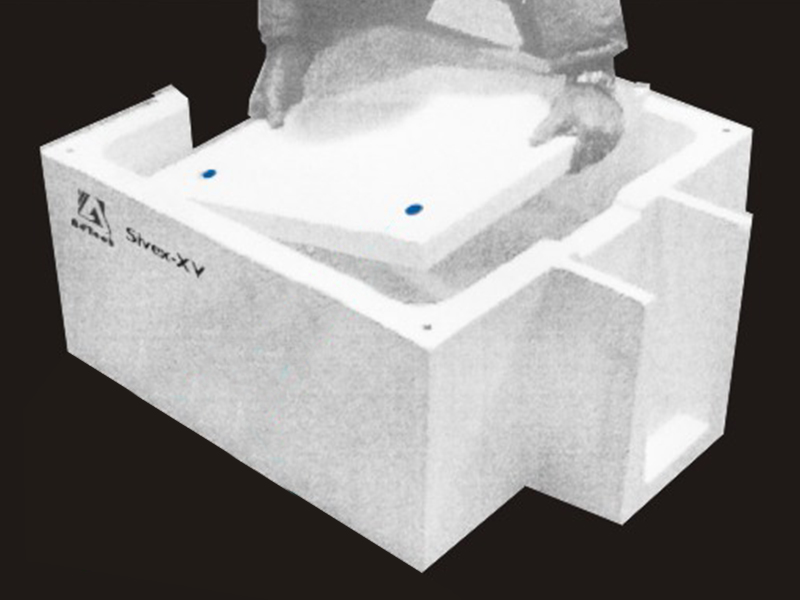

Ceramic Foam Filters For Casting is an advanced product for secondary refining. It has a network of porous structure. With the fluid inclusions continuous deposition, the mesh and channel size becomes smaller and smaller, which improves the effect of filtering. In addition, the filter plate is of high strength and can withstand certain pressure of the liquid metal and metal flow impact, but it is also fragile. The filtering effect is excellent due to its sophisticated structure, uniform quality and large surface area.

Application of Ceramic Foam Filters For Casting

High porosity, heat and shock resistance, high intensity, high specific surface area and good stability, seiving, capturing slag and nidation. Besides filtering molten metal with high temperature, our products can be used as dealing with high temperature gas, catalyst substrate, solid heat exchanger, special packing and so on.