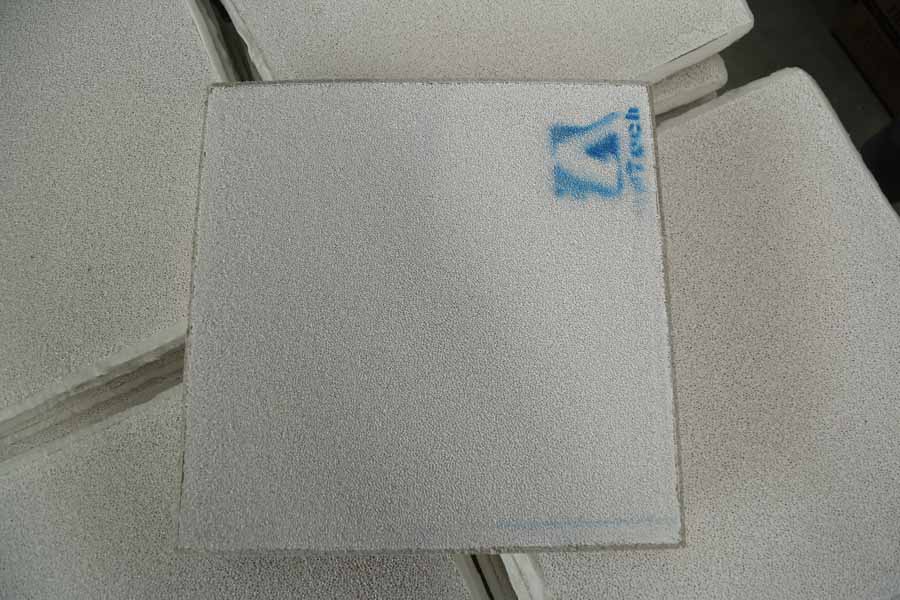

17 Inch Ceramic Foam Filter

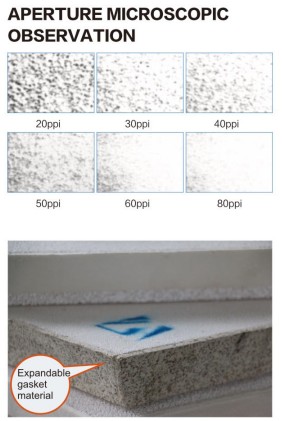

Over time, metal has become one of the key materials in many areas of life, from everyday life to heavy industry. The technology of metal production has developed in the direction of ridding it of impurities and improving properties. Oddly enough, it was in this area that foam rubber found one of its many applications. Special blanks of various sizes and shapes are made from polyurethane foam of various densities, from 10 ppi to 60 ppi, which serve as matrices for processing ceramics – in the production of 17 Inch Ceramic Foam Filter for metal.

17 Inch Ceramic Foam Filter is used in metallurgy and foundry for cleaning metal melt from various inclusions and oxide films, thereby improving the quality of the metal and reducing the number of industrial defects.

There are three main types of 17 Inch Ceramic Foam Filter

1) Ceramic foam filter for aluminum – with an operating temperature of 850 to 1350 degrees.

2) Ceramic foam filter for cast iron – operating temperature of 1480 degrees.

3) Ceramic foam filter for steel – operating temperature 1700 degrees.

Advantages of using metal 17 Inch Ceramic Foam Filter

* Optimum metal filtration, free from impurities

* Optimization of casting speed

* Improved surface quality

* The ability to use direct casting technology on the filter

* Improving the mechanical characteristics of castings and achieving better density of castings

* Decrease in quantity of marriage.