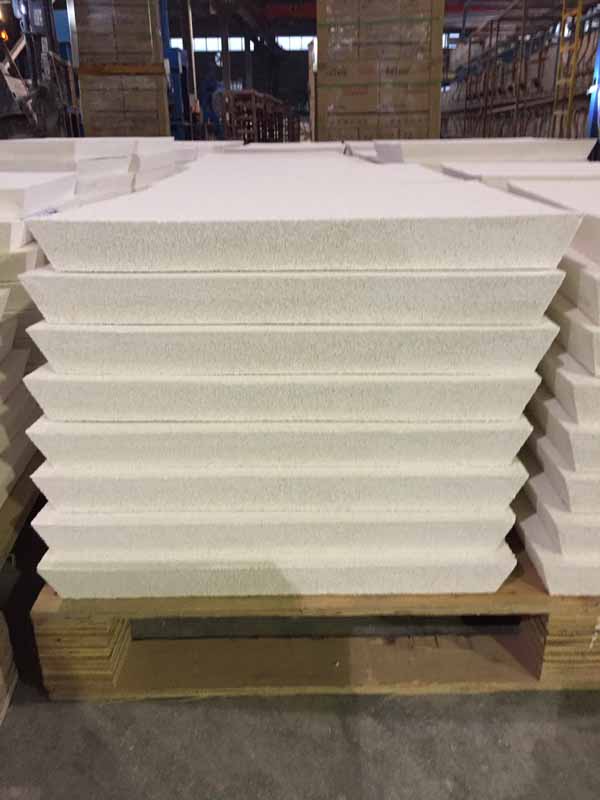

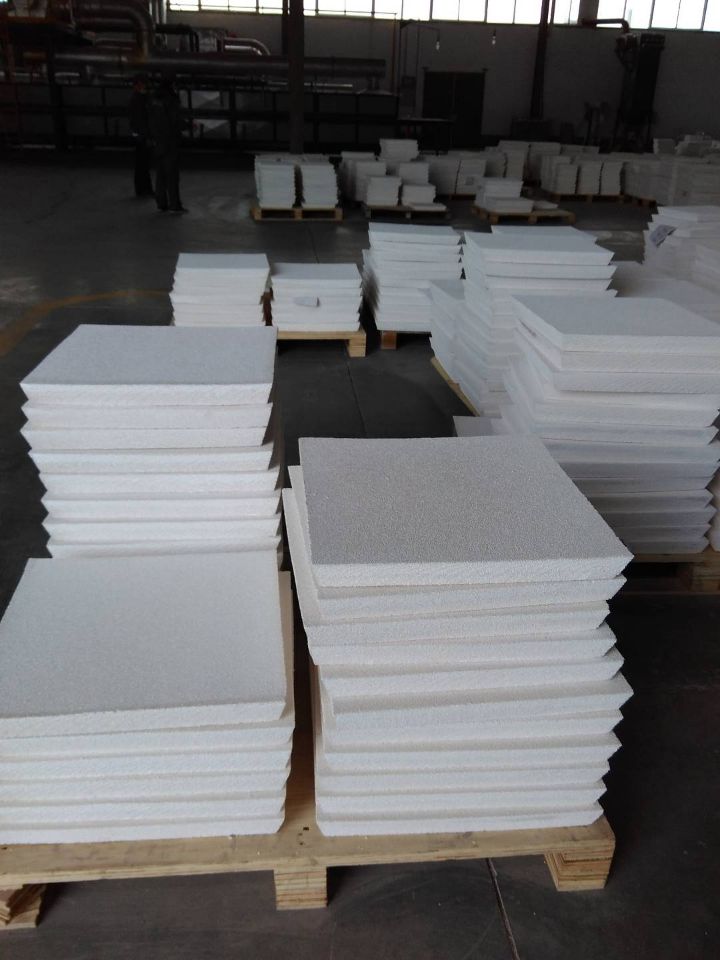

Porous Foam Ceramic Filter

Porous Foam Ceramic Filter removes metal impurities from metal slag and solution, far stronger than other filter media, and combines it with physico-chemical filtration.

The large impurities on the filter surface are physical sieves, retentate and tiny impurities with chemical affinity that are adsorbed onto the filter surface.

Thus, impurities in various sizes of casting products are effectively filtered out, including impurities that are much smaller than the pores that filter impurities. This filtration and combing the entire disordered flow of molten metal reduces turbulence and smoothes the flow of molten metal.

Porous Foam Ceramic Filter Categories

According to its material, ceramic foam filter can be divided into silicon carbide foam ceramic filter, molten iron filter, alumina ceramic foam filter, molten aluminum filter aluminum melt filter and zirconia ceramic foam filter.

Porous Foam Ceramic Filter installation

The filtration efficiency of aluminum ceramic foam ceramic filters is closely related to their proper installation and use.

At the same time, due to the filtration process, it is impossible to neglect the conventional and necessary measures taken to reduce the occurrence of inclusions in process operations such as smelting, furnace treatment and casting. It is also necessary to prevent the contaminated aluminum liquid from being contaminated again after filtration.

The installation and use of Porous Foam Ceramic Filter generally requires attention to the following aspects:

1. The correct choice of filter plate

The size of the filter plate and the number of holes must be selected according to the flow range of the specific casting type, the maximum liquid level of the metal during the filtration process, the total filtration amount, and the cleanliness of the raw materials. Aluminum liquid.

2. Pre-melting filtration treatment can not be ignored

Such as aluminum smelting furnace, holding furnace normal slagging, slag furnace; furnace refining. In particular, an in-line degasser is still necessary because it not only reduces the hydrogen content of the melt, but also removes some non-metallic inclusions.

3. The molten metal filter should be adapted to the square refractory filter box.

Both are suitable for sealing to prevent metal from flowing into the casting box from the gap without being filtered, and to avoid floating in the aluminum water due to the low foam.

4. Preheating before use

Preheat to remove moisture and promote initial transient filtration. The preheating can be performed by electric heating or gas heating. In general, it takes about 15 minutes.

5. In the normal filtration process, no slag is needed to avoid impact and vibration of the filter plate. At the same time, in order to avoid excessive interference with aluminum water, the tank should be filled with aluminum water.

6. After casting, the metal in the flow cell and filter plate is drained. There is a vibrator abroad, placed on the filter plate, shaken for one minute, shake off the remaining 75% of the liquid metal on the filter plate.

7. Finally clean the perimeter, remove the filter plate after solidification.

[…] Ceramic porous foam filter is an open-pore mesh with a sponge-like structure for filtering aluminum melt. It has been widely used worldwide. Ceramic porous foam filter is a filter device that uses ceramic foam as the filter medium. The ceramic foam filter is installed in the filter box between the static furnace and the casting table. After the aluminum liquid is filtered by the filter box, it flows from the static furnace to the crystallizer. […]