High Temperature Resistant Ceramic Foam Filter

Molten metal, particularly molten aluminum, in practice generally contains entrained solids which are deleterious to the final cast metal product. These entrained solids appear as inclusions in the final cast product after the molten metal is solidified and cause the final product to be less ductile or to have poor bright finishing and anodizing characteristics. The inclusions may originate from several sources. For example, the inclusions may originate from surface oxide films which become broken up and are entrained in the resultant molten metal. In addition, the inclusions may originate as insoluble impurities, such as carbides, borides and others or eroded furnace and trough refractories.

It is naturally highly desirable to devise an improved filter for use in removing or minimizing entrained solids from the final cast product, particularly with respect to molten aluminum and especially when the resultant metal is to be used in a decorative product, such as decorative trim or sheet made from aluminum Alloy.

Ceramic foam materials are known to be highly useful in filtering molten metal, particularly molten aluminum. It is highly desirable and it is a principal object of the Adtech to devise a ceramic foam filter which has considerable high temperature resistance so that it can be used on a variety of molten metals and so that the structure thereof is resistant to degradation under the severe conditions of use associated with filtration of molten metal.

It is a high temperature resistant ceramic foam filter as aforesaid which is convenient to prepare and is characterized by reasonable cost.

It is a still Adtech to provide a high temperature resistant foam filter as aforesaid which does not contaminate the melt and does not result in degradation of desirable characteristics in the final metal product.

Further objects and advantages of the present Adtech will appear hereinafter.

SUMMARY OF THE ADTECH FILTER

In accordance with the Adtech it has now been found that the foregoing objects and advantages may be readily obtained.

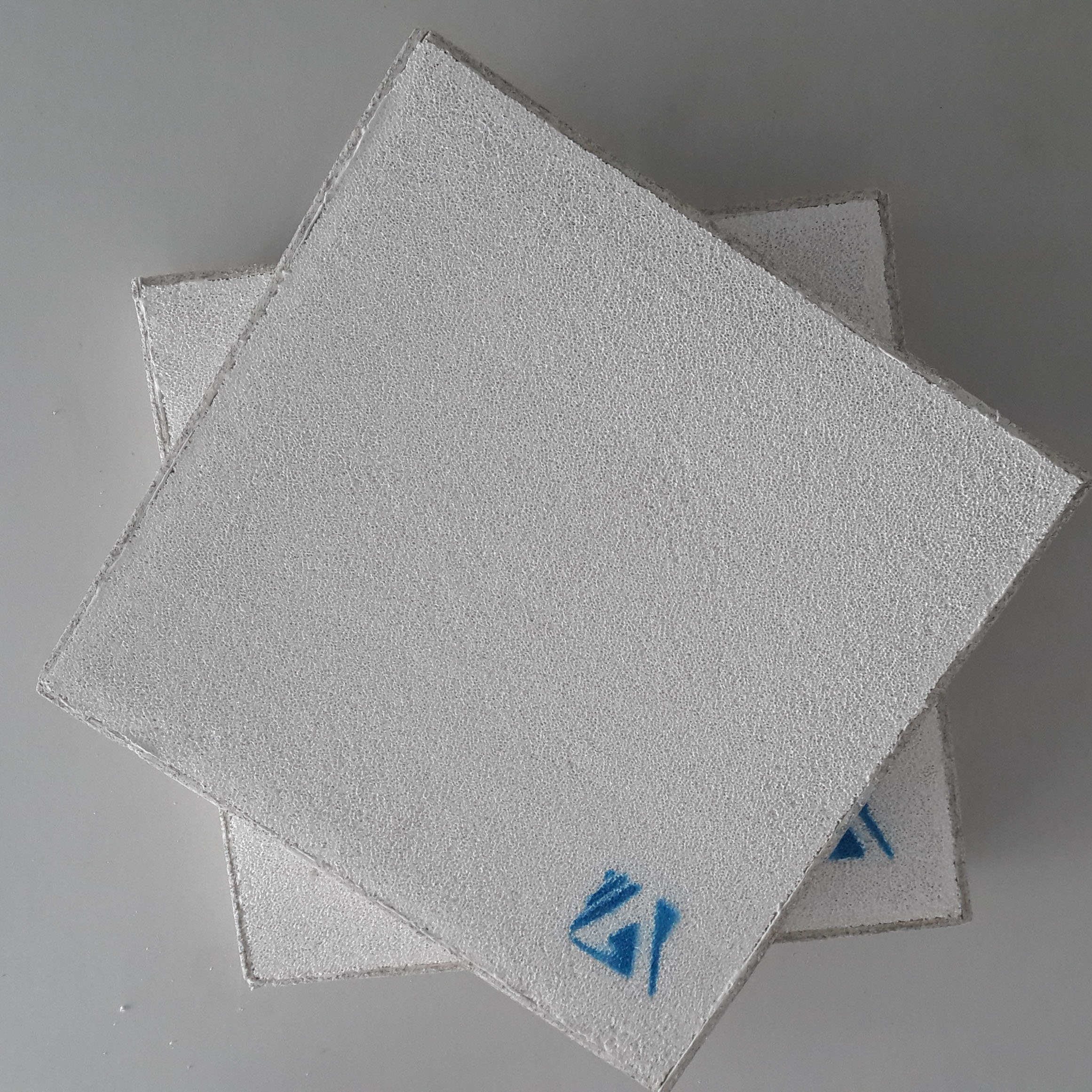

The present Adtech provides a highly efficient, ceramic foam material for use in filtering molten metal, especially molten aluminum. The ceramic foam material of the present Adtech is characterized by having an open cell structure with a plurality of interconnected voids surrounded by a web of said ceramic material. The filter of the present Adtech has a density of less than 30% of the theoretical density for a ceramic material of the same size.

In addition to the foregoing, the Adtech contemplates an aqueous slurry for use in preparing the foregoing high temperature resistant ceramic foam, wherein said slurry contains the materials listed above in the foregoing amounts.

DETAILED DESCRIPTION

In accordance with the present Adtech, the ceramic foam filter described above has been found to be particularly useful in filtering molten metal, especially molten aluminum. The high temperature resistant characteristics of the filter of the present Adtech are particularly useful under the severe use conditions encountered in the filtration of molten metal. Furthermore, the composition of the ceramic filter of the present Adtech has been found to be such that there is no difficulty with contamination of the metal.

The ceramic filter of the present Adtech is a low cost material which may be conveniently used on a disposable basis. The molten metal is poured through the ceramic foam material at a rate of from 5 to 500 and preferably 30 to 100 cubic inches per square inch of filter area per minute and entrained solids are thereby removed from the molten metal.