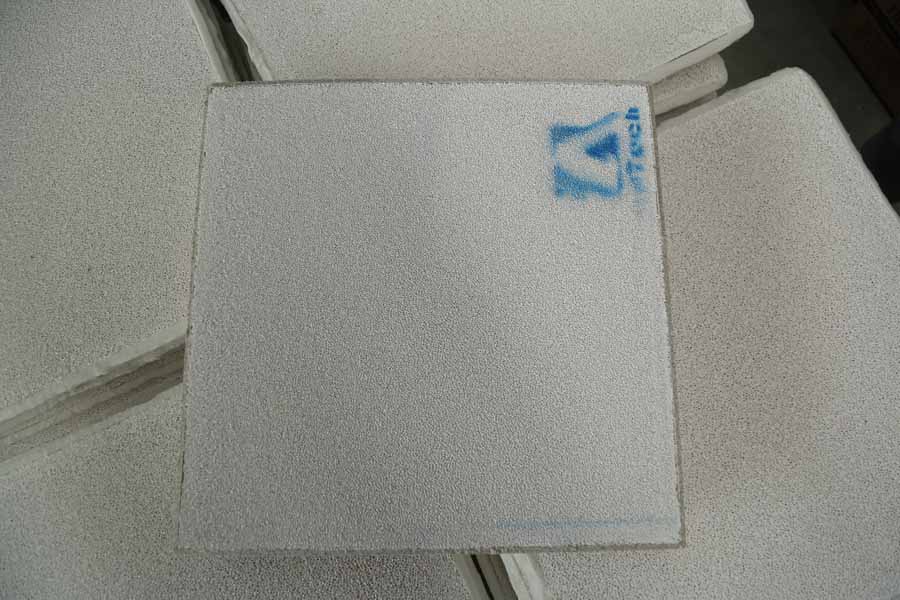

High Grade Ceramic Foam Filter

High Grade Ceramic Foam Filters is produced basing on carrier with solid reticular structure and combined organic foam pores.

The producing procedure is as below, put carrier into the thixotropic alumina slurry, adopt square to center correcting automatic extrusion process, so that slurry evenly deposits in foam skeleton of carrier, after drying solidification.

Then carrier will turn into final product by roasting formed under 1180 ℃ high temperature.

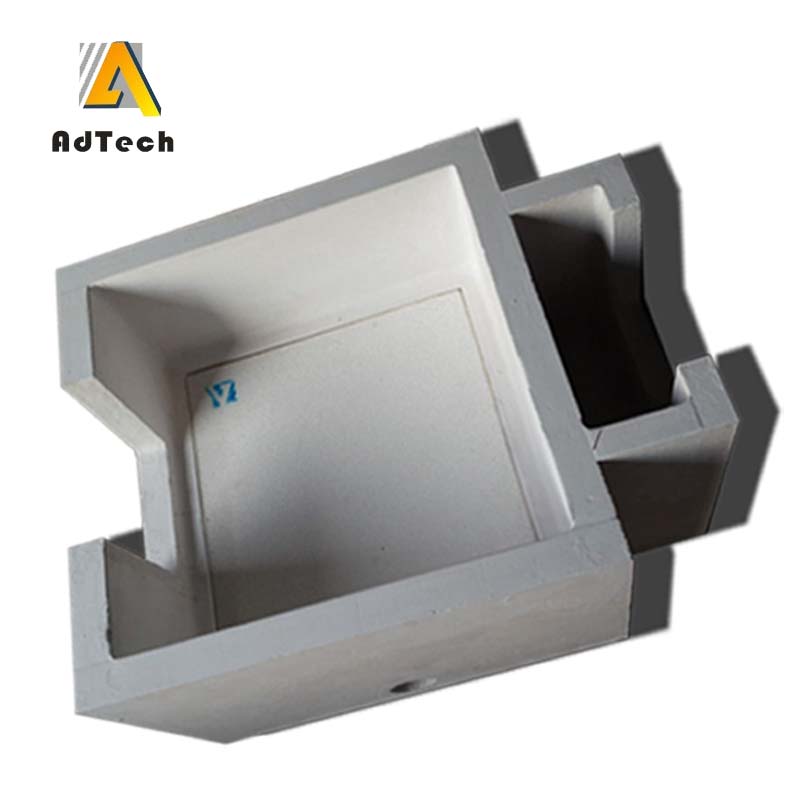

Filter is installed in the filter bowl for filtrating impurity in molten aluminum alloy, which helps to meet the requirement of production in high value-added, high-tech performance aluminum alloy precision casting, such as computer hard drive, PS baseboard for printing, canning materials, fan blades for turbojet engine, etc.

Advantages for High Grade Ceramic Foam Filter

Adopt adsorption principle for filter, can effectively remove big piece inclusions in molten aluminum, and effectively adsorb tiny inclusions.

No broken bits drop out, effectively reduce the pollution of molten aluminum.

Superior thermal shock resistance, improve erosion resistance ability of molten metal.

Automatic flow production,3 calibration procedures,precision size,fit the filter bowl tightly.

Improve the surface appearance and performance, purify molten aluminum.

These filters are solely used in aluminum casting. Currently, diverse sizes and thickness are being offered from the market leading suppliers. You have to choose the right one as per your requirements. You can order a customized size, if your requirement is not fitting to the common sizes. To avoid re-oxidation of the molten aluminum during casting, you can go for pressure-free casting technique. It boosts the productivity of the manufacturer while keeps the filter ready for next big consignments.

Mostly it is used only for iron, steel and stainless steel casting. The most advanced ZrO2 filters changed the market scenario. For Cobalt- and Nickel-based alloys casting, this mechanism works great. Mainly it is a great performer in low-carbon as well as ultra-low-carbon steels casting.

High Grade Ceramic Foam Filters – It is the most used and versatile option for casting aluminum, brass, bronze, copper, iron, and steel also. Mostly it is used in iron and non-ferrous casting units. You just need to find the accurate thickness of the filter to amplify the bending strength for higher productivity.