Ceramic Filter Xinfa Aluminium Indonesia from China adopts the principle of adsorption, which can effectively remove large inclusions in molten aluminum and effectively adsorb small inclusions. It is widely used in various branches of Chinalco.

Chinalco’s engineers provide Ceramic Filter feedback

1. No damage, effectively reducing the pollution of molten aluminum.

2. Excellent thermal shock resistance, improving the erosion resistance of the molten metal.

3. After use, it is not broken and is easy to clean.

A special aluminum foam ceramic filter is used to remove the inclusions generated between the purification system and the mold table.

When the metal is solid, the ability of the ceramic foam filter to capture these inclusions is important to keep the ingot clean.

In Adtech’s factories, engineers constantly strive to ensure that our customers have the best technology on the market, enabling our customers to produce the highest quality aluminum rods, aluminum ingots, or aluminum foils.

Keywords=aluminum ceramic foam filter, ceramic foam filters, ceramic filter plate, aluminum shaft plate, silicon carbide foam ceramic filter, alumina ceramic filter, alumina foam filter, molten metal filter, cast filter, Cast filter.

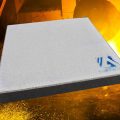

Molten aluminum removal technology

In the existing aluminum rod production lines in the Indonesian market, most of the remelted aluminum ingots are smelted from the smelting furnace through the ladle directly into the casting ladle, or the ladle filter box is cast in the ladle between the launders. In the casting process, choosing high-quality Ceramic Filter Xinfa Aluminium Indonesia can avoid the solidification of the aluminum liquid in the filter box due to parking, and the filter plate is scrapped.

In response to this process defect, our engineers and technicians have gone through many years of process improvement and practice.

The specially customized aluminum melting filter box protects the filter plate by setting a partition baffle in the filter device. At the same time, according to the buoyancy principle in physics, it also plays a role in purification. This technology is used in conjunction with the aluminum liquid purification device used by our company. The purpose is to achieve the final purification of aluminum wire through the combination of two sets of devices.