Alumina Ceramic Foam Filter for Cast House Molten Aluminium Filtration

Alumina Ceramic Foam Filter is mainly for the filtration of aluminum and alloys in foundries and cast houses.With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow,and then the filtered metal is significantly cleaner. Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

MODEL NAME: PAL

DESCRIPTION: Alumina ceramic foam filter

APPLICATION: For the filtration of molten aluminum

Reduce scrap related to inclusions

Reduce costs related to inclusion defects

Increase productivity with higher extrusion or rolling speeds

Increase casting flexibility with easy alloy changes

No holding metal

FEATURES:

Superior dimensional tolerances

Stable chemical composition

Highest filtration efficiency

Excellent strength

Resistant to corrosion attack by molten aluminum and alloys

Beveled edges and compressible gasket

Ceramic filter plate instructions

Inspect and clean the surface of the filter box to keep the filter box clean and free from damage.

Gently put the filter plate into the filter box and press the gasket around the filter plate by hand to prevent the aluminum liquid from flowing or floating.

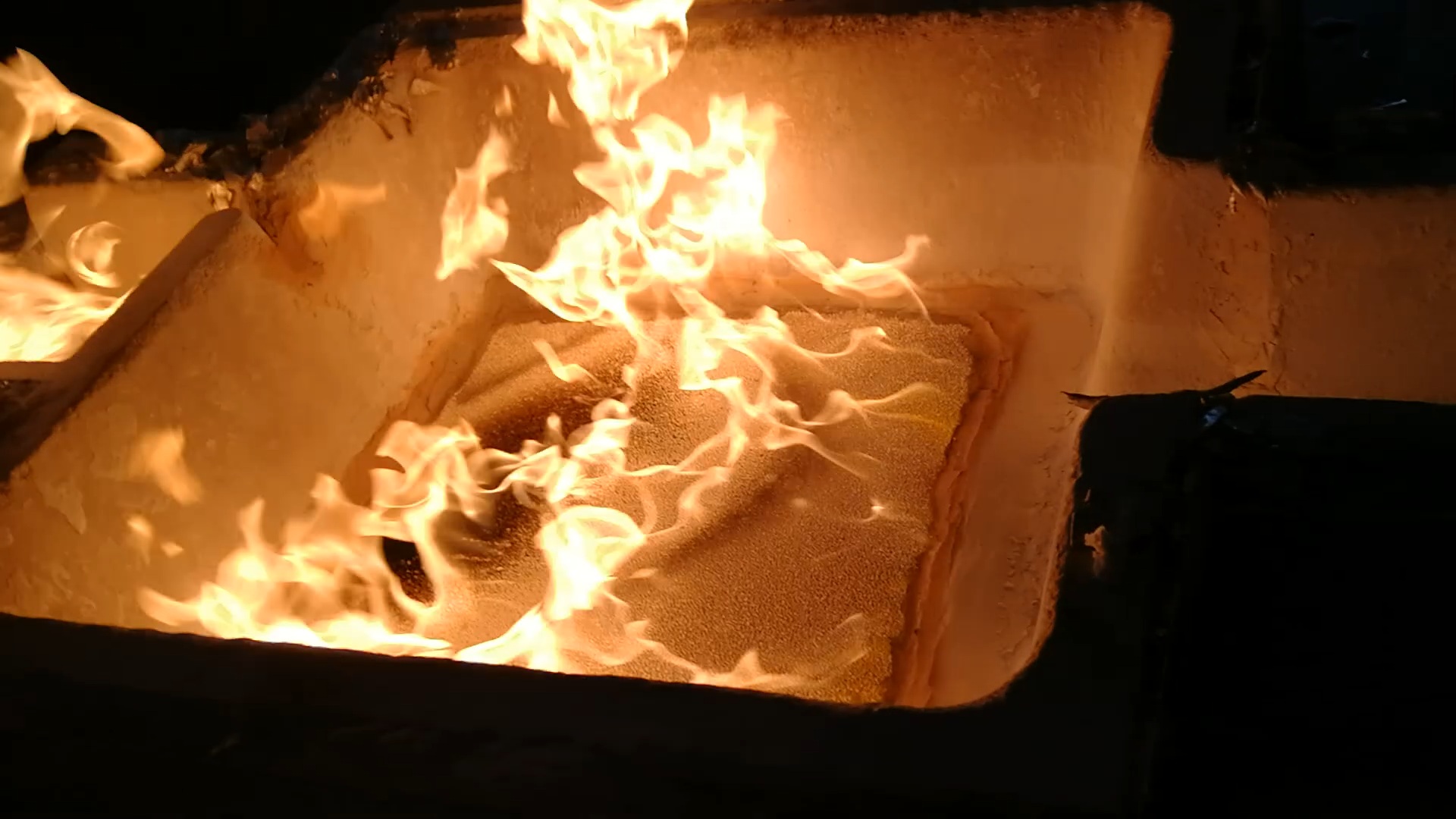

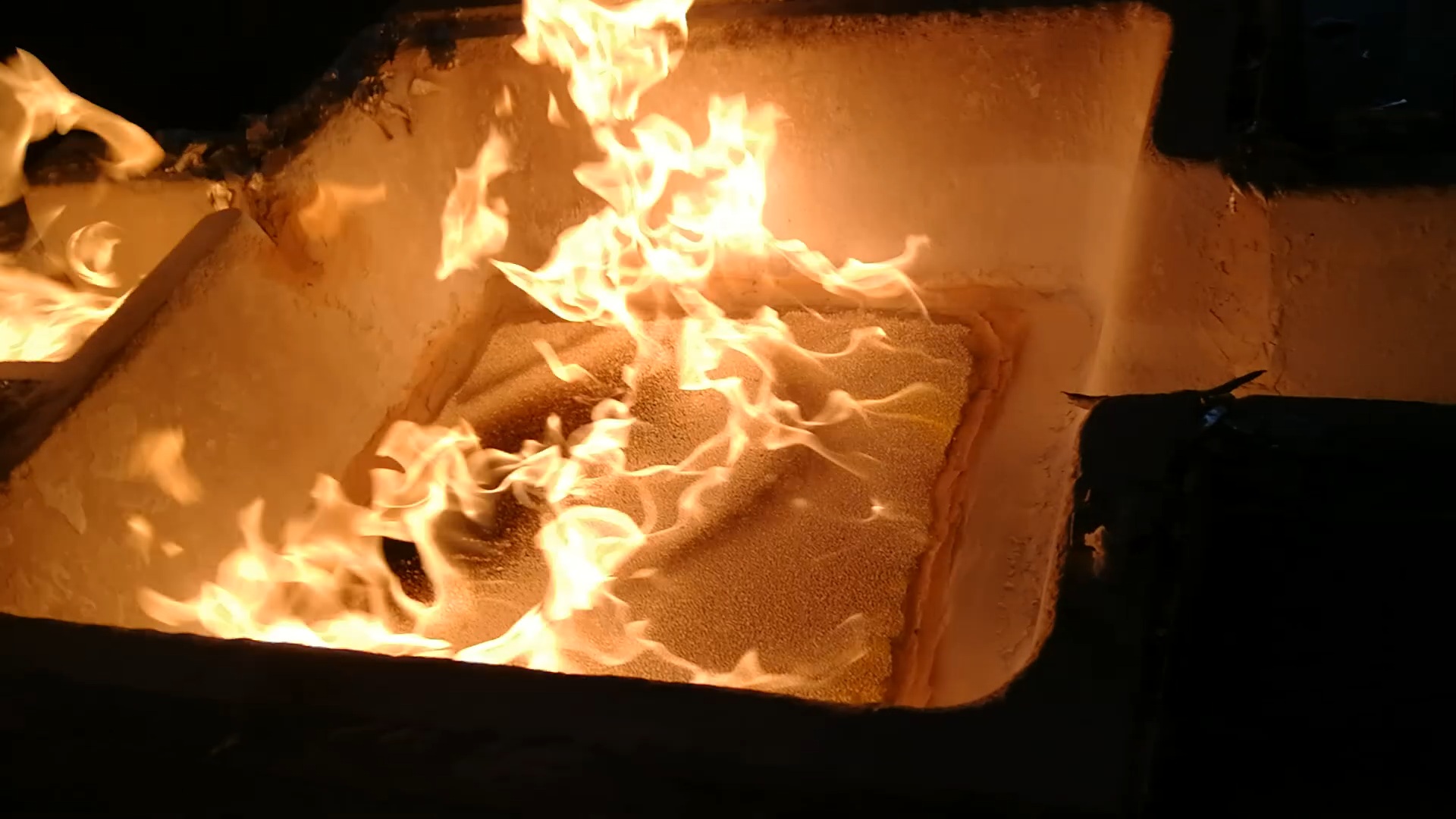

The filter box and the filter plate are uniformly preheated to be close to the temperature of the aluminum liquid, and the preheating temperature of the filter plate is not lower than 260 °C. Preheating to remove the adsorbed moisture helps to facilitate the initial initial filter pore opening, preventing the heat expansion and contraction from causing partial pore blockage to the filter plate. Preheating can be heated by electricity or gas, and heated normally for 15-30 minutes.

Pay attention to the change of the aluminum hydraulic head during casting, and maintain the flow of the normal demand aluminum liquid. The normal starting pressure head is 100-150mm. When the aluminum liquid begins to pass, the pressure head will drop below 75-100mm, and then the pressure head will gradually increase.

During the normal filtration process, avoid knocking and shaking the filter plate. At the same time, the launder should be filled with aluminum water to avoid the aluminum liquid too large and too small disturbance.

After the filtration is finished, remove the filter plate in time and clean the filter box.