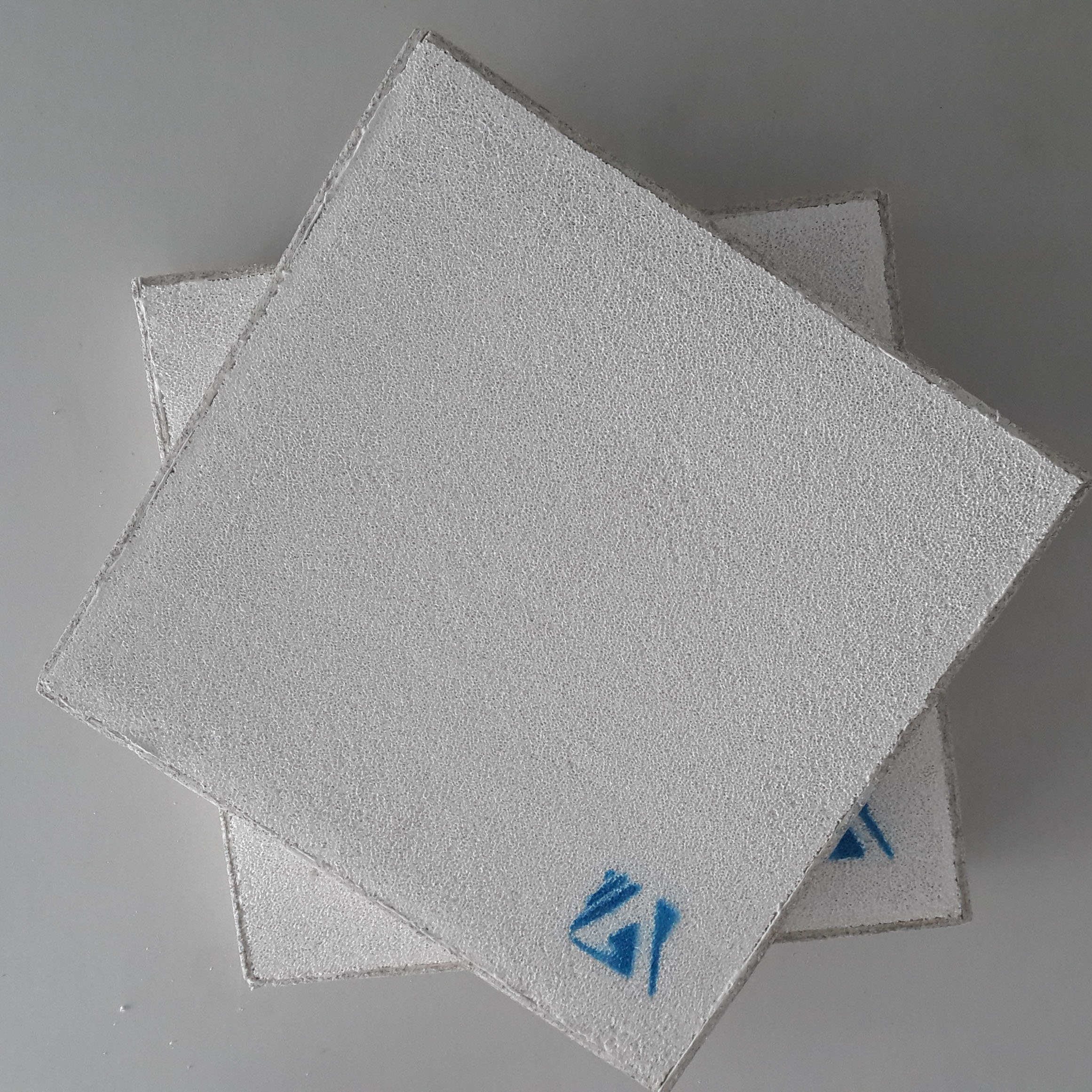

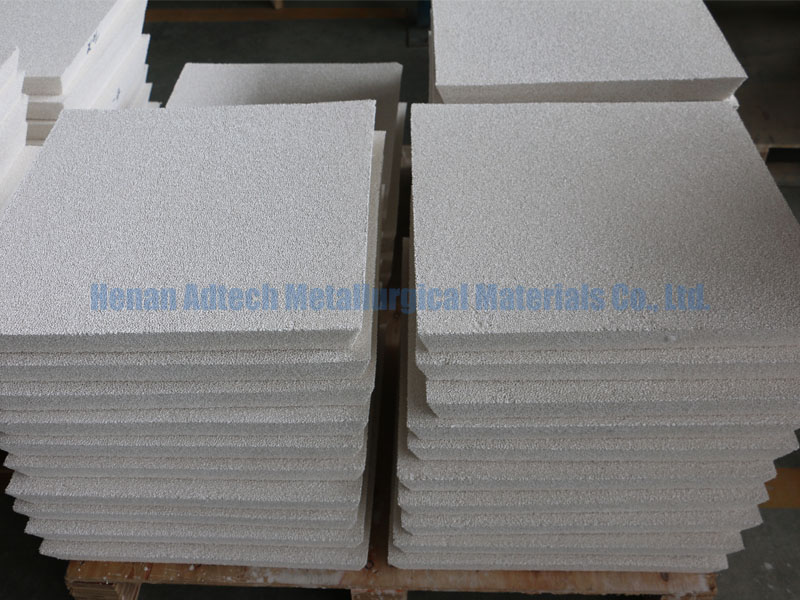

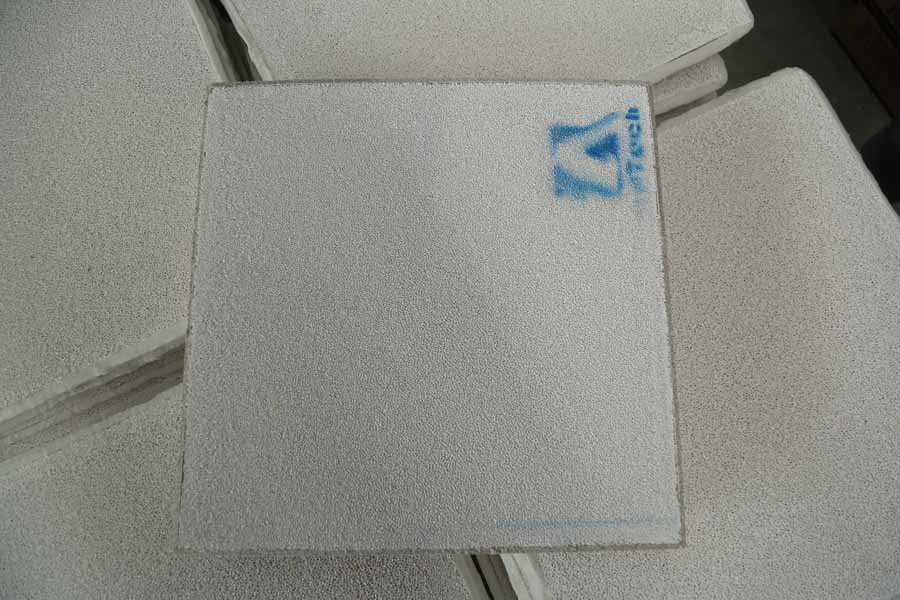

Ceramic Foam Filter Factory

The Ceramic Foam Filter Factory can be quickly fired in the range of 1350 ° C to 1460 ° C, and the firing rate is higher than 95%. Product performance and physical and chemical indicators are in line with production and use requirements.

The Ceramic Foam Filter Factory removes inclusions from molten aluminum alloys.

The filter plate can effectively remove inclusions in the aluminum melt, is inexpensive, and is convenient to use.

In order to improve product quality, this paper proposes a series of recommendations on how to use ceramic foam filter.

Various aspects of the use of filter plates are discussed, including the design and construction of the filter basin, the choice of filter plate size and porosity, the seal lining and its function, the heating, perfusion, normal filtration and sample taking of the filter plates.

Examples of improper use of melt cleanliness and product quality.

Related posts:

Ceramic Foam Filter Made In China

Ceramic Foam Filter Made In China

Aluminum Factory Filter Plate

Aluminum Factory Filter Plate

Ceramic Filter Factory manufacturer Adtech

Ceramic Filter Factory manufacturer Adtech

Adtech visits the Russian Aluminium Factory to discuss in-depth cooperation

Adtech visits the Russian Aluminium Factory to discuss in-depth cooperation

A university professor and related leaders of the aluminum factory visited AdTech

A university professor and related leaders of the aluminum factory visited AdTech

Indonesian Aluminum Industry Exhibition

Indonesian Aluminum Industry Exhibition

Ceramic candle filter manufacturers

Ceramic candle filter manufacturers

Aluminium Siberia Ceramic Foam Filter Supplier

Aluminium Siberia Ceramic Foam Filter Supplier

An old friend of Colombian old customers

An old friend of Colombian old customers

Cordierite Porous Ceramic Filter

Cordierite Porous Ceramic Filter

Aluminium Ceramic Foam Filter Purchasing

Aluminium Ceramic Foam Filter Purchasing

Porous Ceramic Filter Foam

Porous Ceramic Filter Foam

Metal Foundry Foam Filter

Metal Foundry Foam Filter

Ceramic Foam Filter Installation

Ceramic Foam Filter Installation