Porous Ceramic Filter

Metals and metallic products have a special connotation with human civilization.

It is considered to be one of the primitive material that human have mastered to use. However, all metals are not very stable in its rawest form.

This form of metals may not have the optimum metallic properties and therefore it requires purification.

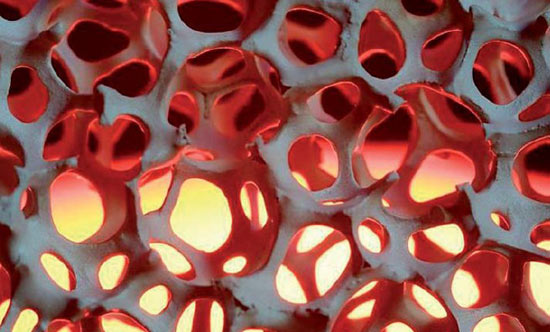

Purification process of molten metal require ceramic ceramic foam filter, which ensure that all the impurities has been removed from the metallic solution.

Once this process is achieve, metal is ready to be used in different types of applications through different processes.

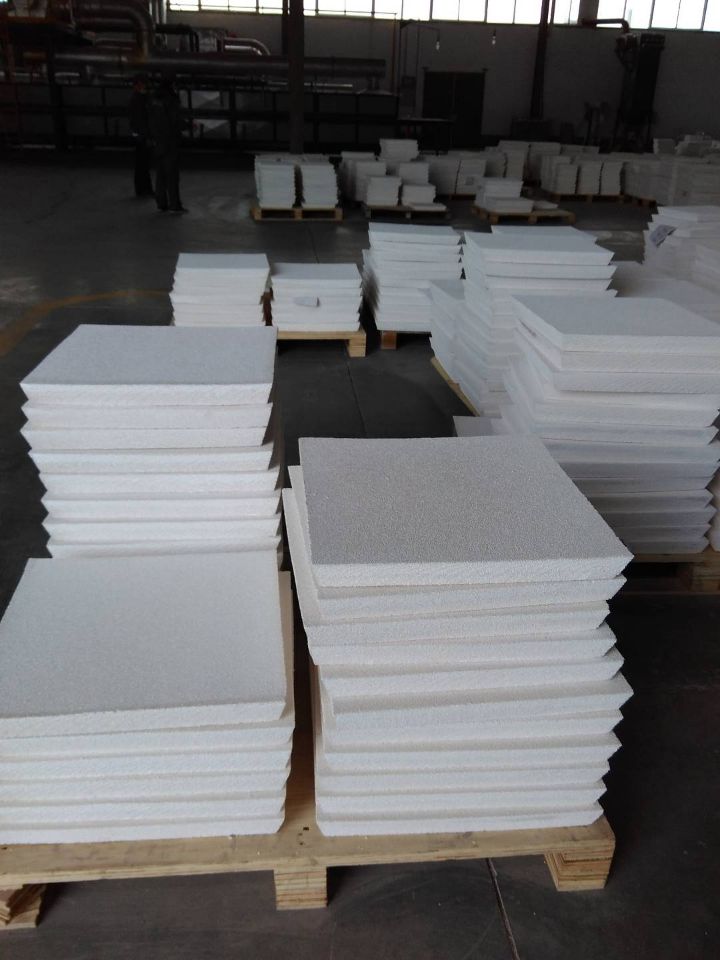

Porous Ceramic Filter mainly for filtration of aluminum and alloys in foundries and cast houses.

With the excellent resistance to attack and corrosion from molten aluminum, the filter can effectively remove inclusions, reduce trapped gas and provide laminar flow and then the filtered metal is significantly cleaner.

Cleaner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Porous Ceramic Filter Features

-Reduce scrap related to inclusions.

-Reduce costs related to inclusion defects.

-Increase productivity with higher extrusion or rolling speeds.

-Increase casting flexibility with easy alloy changes.

-No holding metal.

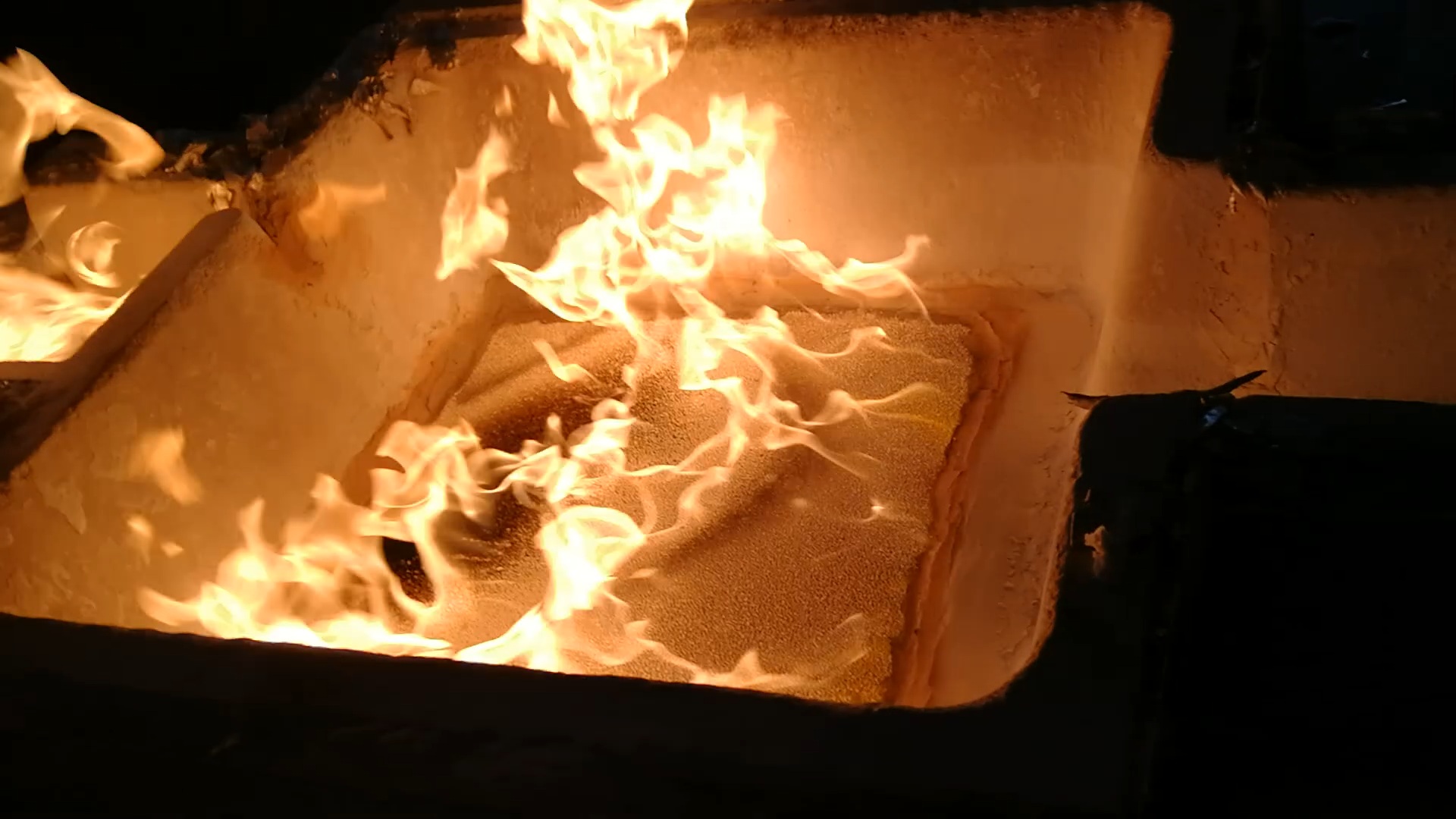

Porous Ceramic Filter Pre heating:

Alumina ceramic foam filters are normally applied by placing them into a filter box. It is important to pre-heat both filter and filter box before use. During pre-heat care must be taken to control both heat up rate and temperature distribution. This minimizes thermal shock and stresses in the filters and filter box refractory.

Porous Ceramic Filter Priming:

Before a filter can be used, it must be completely wetted by liquid metal. This happens during the start-up of the casting operation. The amount of metallostatic pressure (or priming head) required to wet filters depends on alloy, metal temperature, pre-heat uniformity, pre-heat temperature, incoming metal quality,pre-filter treatments and on the cell size of the filter.