Casting Ceramic Foam Filter Aluminium Metal Filtration

Aluminum industrial Casting Ceramic Foam Filter Characterization

Structural characterization of specific reactions in pore size, pore distribution, pore shape and porosity;

The pore structure of the membrane is closely related to its filtration transfer performance. The pore size and pore size distribution are the most important parameters of the membrane structure, which directly affect the transfer characteristics of the fluid in the membrane and determine the separation and filtration performance of the membrane surface.

The quality of aluminum industrial Casting Ceramic Foam Filter in the smelting of aluminum melts is important, which greatly affects the subsequent processing properties and the quality of the final product.

Therefore, all countries in the world attach great importance to the purification of aluminum melt; there are many reasons for aluminum pollution. On the one hand, during the smelting process, aluminum is exposed to the furnace atmosphere in a molten or semi-molten state, which is prone to oxidation and easily reacts with water vapor. Hydrogen is easy to form various forms of non-metallic slag, as well as coarse intermetallic particles and the like.

On the other hand, part of the waste material in the composition charge carries some non-aluminum impurities during the circulation. Since the waste comes from the process waste and waste of the various processes of the factory and the waste outside the factory, the route is different, the composition is complex, and the quality is also poor.

These impurities tend to cause bubbles and inclusions in the slab, which seriously affect the purity of the metal melt, thereby further affecting the processing properties, mechanical properties, corrosion resistance and appearance quality of the product.

The aluminum industrial Casting Ceramic Foam Filter can effectively remove all kinds of fineness in the aluminum water to the micron-sized inclusions, so that the aluminum water becomes a smooth laminar flow, which is favorable for filling.

It has a unique corundum structure, good mechanical strength and chemical stability, superior aluminum washability; tightly controlled hole size and through-hole ratio for stable filtration.

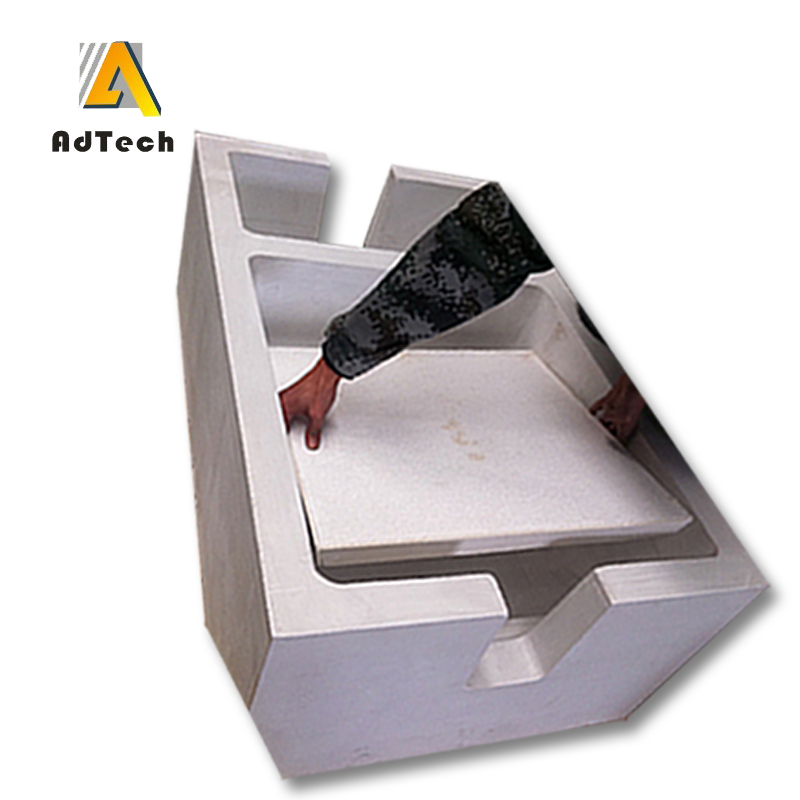

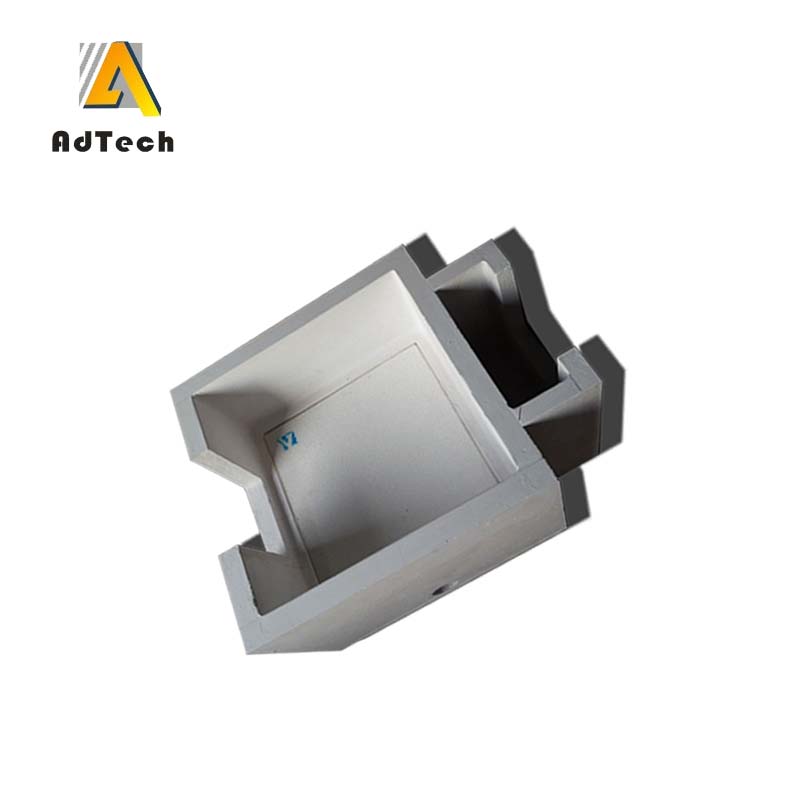

The ceramic filter plate is surrounded by a sealed ceramic fiber gasket, which helps the filter plate to seal in the filter box, ensuring no metal loss.

This product is mainly used in the purification process of aluminum and aluminum alloy production.

Correct selection of ceramic foam filterto improve the cleanliness of aluminum melt

The selection of the ceramic foam filter plate is firstly determined according to the amount of impurities in the aluminum melt and the degree of quality required for the final cast product of the melt transfer flow rate.

1. The amount of impurities is high, and the quality of the cast product is general. The foam ceramic filter plate with larger mesh mesh can be selected, and a glass fiber cloth coarse filter is added in front of the filter plate. At this time, it is important to use a glass fiber cloth for coarse filtration in semi-continuous casting. It can intercept the slag and the slag washed by the launder when the eye is opened.

In order to prevent blockage of the filter plate.

2. The quality of cast products is high, and the new type of foam ceramic filter with small mesh size is selected. For example, AdTech ceramic filter plate adopts three-dimensional network structure and organic bubble body connected with pores as carrier. The intrusion into the thixotropy alumina material slurry is carried out by a four-square correction center distance automatic extrusion process, so that the slurry is uniformly applied to the carrier foam skeleton, and is baked and solidified at a high temperature of 1180 ° C. It is installed in the filter box for the impurity filtration of aluminum alloy liquid, and it can meet the high-value-added and high-tech aluminum alloy precision casting of aviation and transportation. Such as: computer hard disk, PS board base for printing, cans, jet turbine engine fan blades and other products, to achieve the desired cleanliness, get good results.

3. The specification of the filter plate is determined by the flow rate and total throughput of the melt. The flow rate is large, the total throughput is large, and the filter plate has small holes, and a larger size is selected.

Select the filter plate should also look at its color, shoot its body, burn its contents.

1. The color is pure and no impurity, indicating that the material is uniform; the hand is not sticky, indicating that the surface is not sprayed with adhesive, and will not cause secondary pollution.

2. With one hand holding the filter plate, the other hand with the applause type, slap the filter plate with ease, and continuously drop the ceramsite residue, indicating that it is a poor quality filter plate, which will cause secondary pollution of aluminum liquid.

3. Use an open flame or electric heating to heat up to red. Immediately cool at room temperature without cracking and slag, indicating a good filter plate.

The effective specific surface area or porosity calculation of the foam should be carefully evaluated when purchasing the filter. The mesh surface homogenization state of the filter plate can be observed, and then the cross-sectional mesh homogenization state is observed. If possible, the porosity can be calculated by the drainage method. The three-dimensional mesh is homogeneous and the porosity is relatively large, which is an excellent foam ceramic filter plate.

AdTech Metallurgical Materials Co.,Ltd.

Email:sales@adtechamm.com