Rotary Aluminium Degassing Machine mainly processes molten aluminum containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which are removed after being processed by degassing equipment.

During the smelting process of aluminum alloy, the molten aluminum will react with water vapor to produce hydrogen and dissolve into the molten aluminum. When the molten aluminum solidifies, the hydrogen will be removed from the molten aluminum.

If the hydrogen content in the molten aluminum is too high, pores are easily formed in the castings, and the mechanical properties of the castings will decrease. In severe cases, the castings will be scrapped.

Hydrogen is a harmful gas in molten aluminum. The pre-furnace detection of the hydrogen content of molten aluminum is an important process to ensure the quality of castings. Especially when large-capacity furnaces are used for mass production, the use of molten aluminum degassing machine to remove hydrogen and slag will Become indispensable.

If the hydrogen content in the alloy ingot or cast-rolled sheet is too high, it will appear in the aluminum alloy product in the form of hydrogen bubbles because it is too late to escape during the solidification process.

When the alloy slab or cast-rolled coil is rolled to a certain thickness, holes will appear at the place where the hydrogen bubbles appear, which will cause the rolled strip to break and cause the product to be scrapped.

In order to control the hydrogen content in the aluminum alloy products within the required range, most of the molten aluminum is refined by the flux method. The flux generally contains toxic elements, which corrodes the crucible and tools of the melting furnace seriously, and pollutes the environment and human health. Can meet people’s needs.

Rotary Aluminium Degassing Machine is a kind of pollution-free green aluminum liquid purification equipment

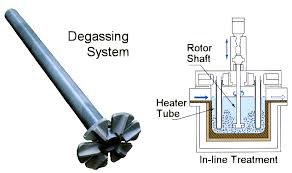

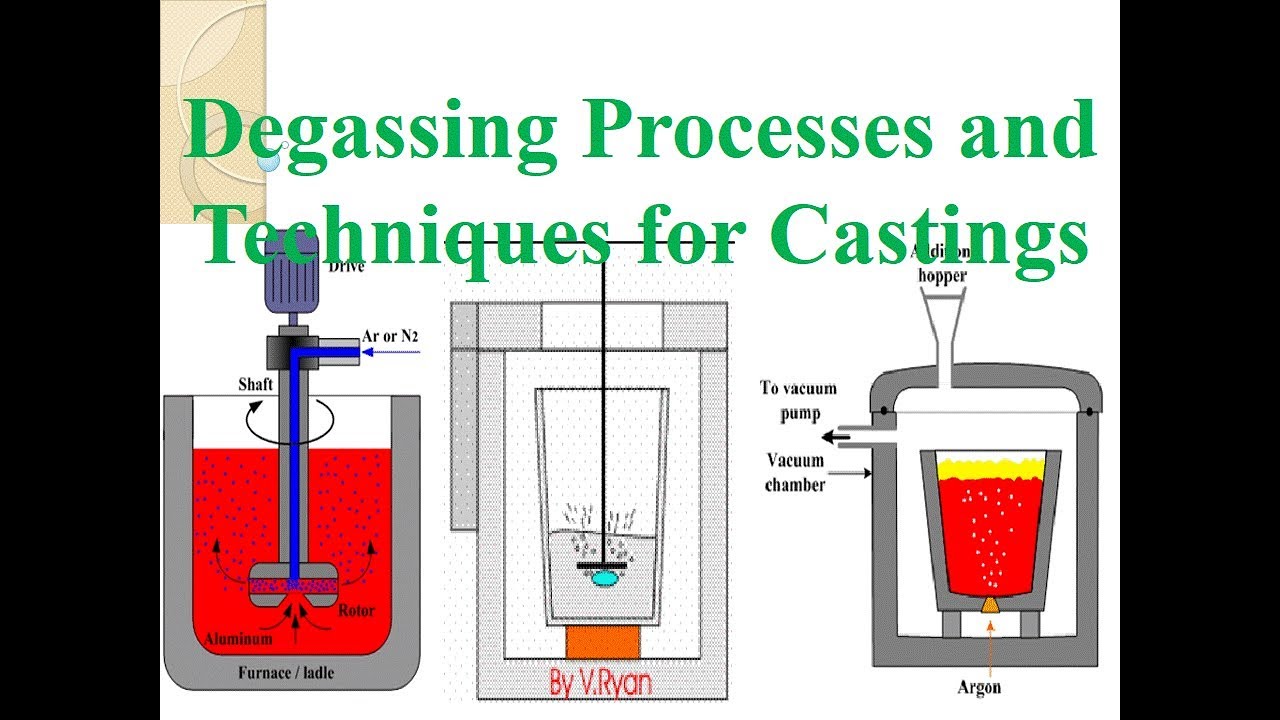

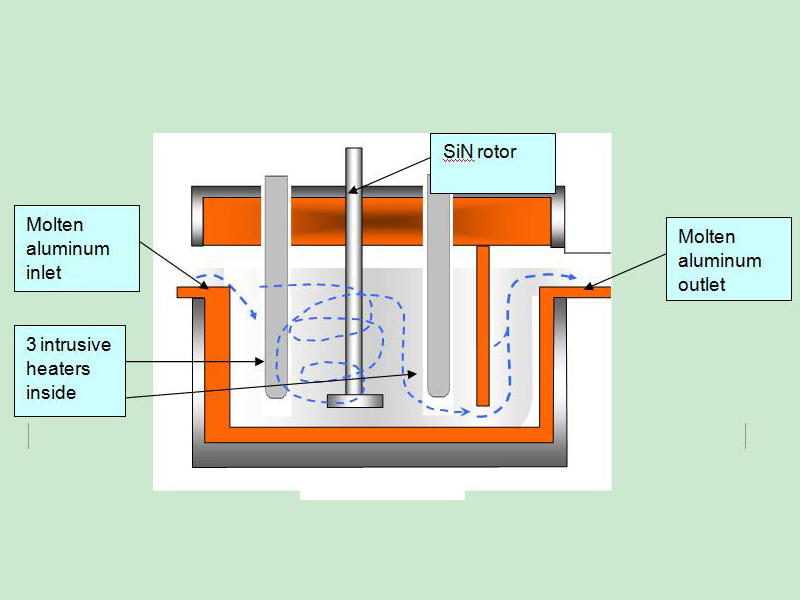

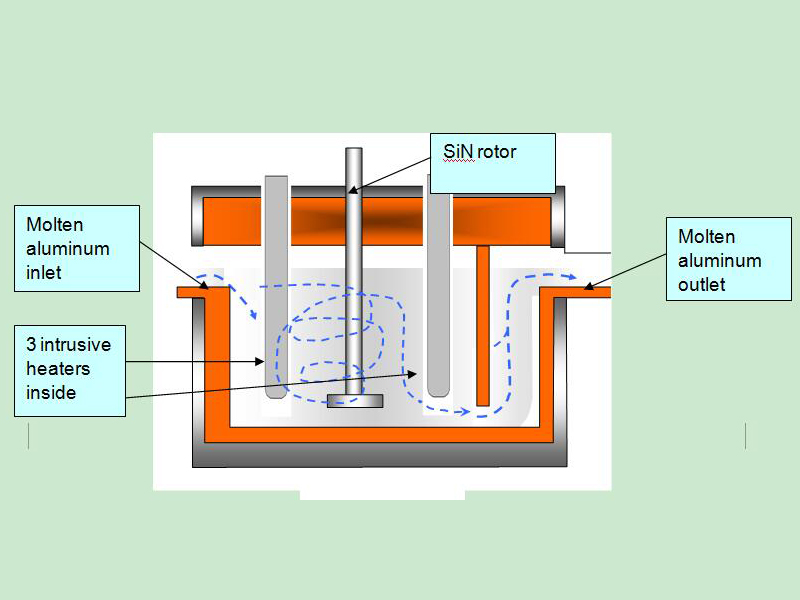

The molten aluminum is stirred by a controlled rotating silicon nitride rotor. Nitrogen is pressed into the molten aluminum through the rotor and dispersed into tiny bubbles to make it evenly dispersed in the molten metal.

The hydrogen in the molten aluminum continuously diffuses into the bubbles, and at the same time some non-metallic inclusions in the molten aluminum are adsorbed on the surface of the bubbles.

Useless hydrogen and nitrogen bubbles adhered to some non-metallic inclusions float to the liquid surface.

The slag skimming achieves the removal of hydrogen and oxidized inclusions.

Rotary Aluminium Degassing Machine has high efficiency and good effect. It does not affect the production process. It can improve the purity of molten aluminum in a short time, reduce the scrap rate, increase production efficiency, improve the mechanical properties of castings, and enhance the competitiveness of products.