Improve the purification effect of aluminum melt

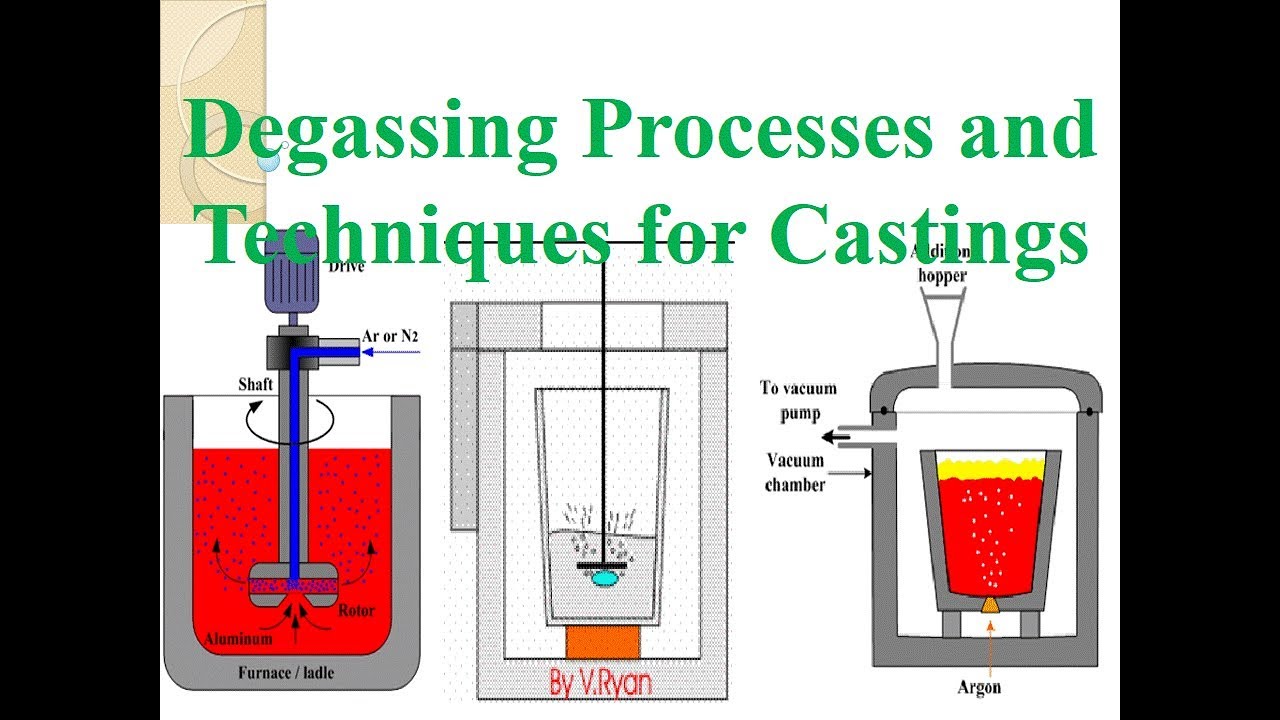

The purification technology of aluminum alloy melt furnace can be further divided into adsorption purification treatment technology and non-adsorption purification treatment technology according to the purification mechanism.

The adsorption method mainly relies on the refining agent to produce the adsorption and oxidation inclusions, and at the same time removes the oxidation inclusions and the hydrogen attached to the surface to achieve the purpose of purifying the aluminum liquid.

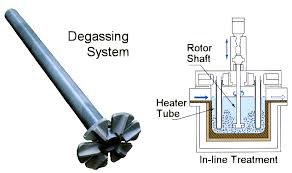

Non-adsorption method relies on other physical and chemical effects to achieve the purpose of purifying aluminum liquid. The refining action of the adsorption method only occurs at the adsorption interface, and the non-adsorption method acts on the entire aluminum liquid at the same time. The adsorption purification treatment technology mainly includes inert gas purge, active gas purge, mixed gas purge, chlorine salt (hexachloroethane) purification, non-toxic refining agent purification, flux refining and the like.

In the adsorption purification treatment technology, chlorine gas refining is used, and aluminum trichloride is formed with liquid aluminum, and hydrogen chloride is generated by hydrogen gas, which has both physical and chemical purification effects, and the refining effect is obvious.

It causes serious damage to the environment and equipment, and chlorine is the most fundamental culprit in destroying the ozone layer of the atmosphere.

Later, it was changed to nitrogen refining, and even high-purity nitrogen refining was used, which not only increased the cost but also had a poor refining effect.

Although people have realized the seriousness of the problem and are striving to improve the process, many years of efforts are still unsatisfactory. Non-toxic and non-polluting refining processes (such as refining with inert gases such as nitrogen and argon) often cannot reach such as serious The refining effect that can be achieved by environmentally contaminated chlorine refining treatment.

In recent years, mixed gas refining is widely used in foreign countries, that is, adding a small amount of active gas in high-purity nitrogen or argon gas, while strengthening the aluminum alloy melt to remove hydrogen, it is beneficial to remove inclusions inside the aluminum alloy melt and The surface of the aluminum alloy melt causes dry slag, which can achieve a good refining effect, and can artificially control the amount of chlorine gas mixed, which has little impact on the environment.

In the non-adsorption purification treatment technology, the rare earth element hydrogen storage method (chemical hydrogen fixation method) utilizes the special electronic structure and physical and chemical properties of the rare earth element.

And the formation of high-melting-point compound dispersion particles, the absorption of a large amount of hydrogen in the aluminum alloy melt in solid form, plays an increasingly important role in the purification of aluminum alloy melt.

At the same time, rare earth elements have also been widely used in metamorphic treatment. Therefore, rare earth chemical solid-hydrogen purification of aluminum alloy melt has become a development direction of new aluminum alloy melt refining agents.