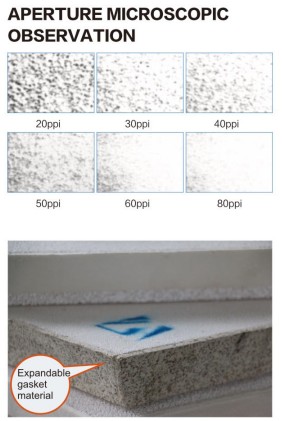

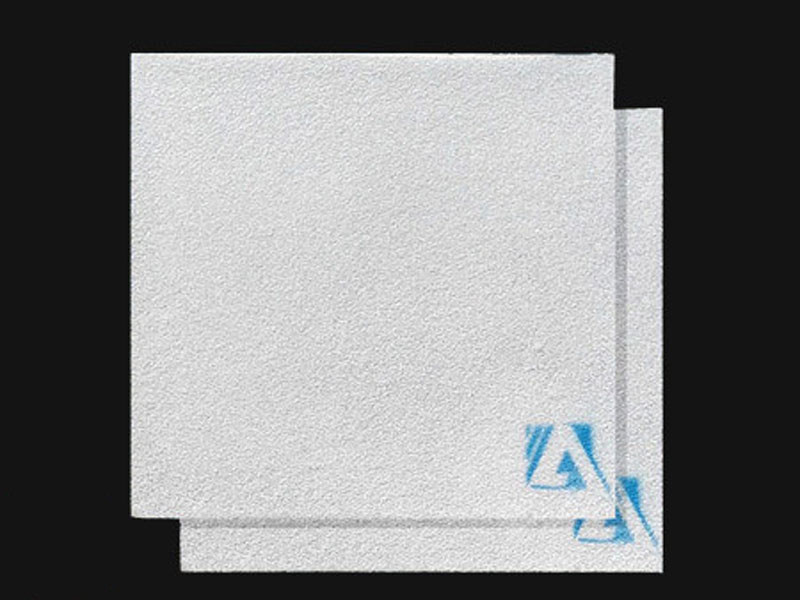

Alu Ceramic Foam Filter can effectively remove large impurities in molten aluminum and adsorb micron-level fine particles of impurities, thereby improving surface quality, improving product performance, improving microstructure and increasing output.

It is widely used in the production of aluminum profile, aluminum foil and aluminum alloy.

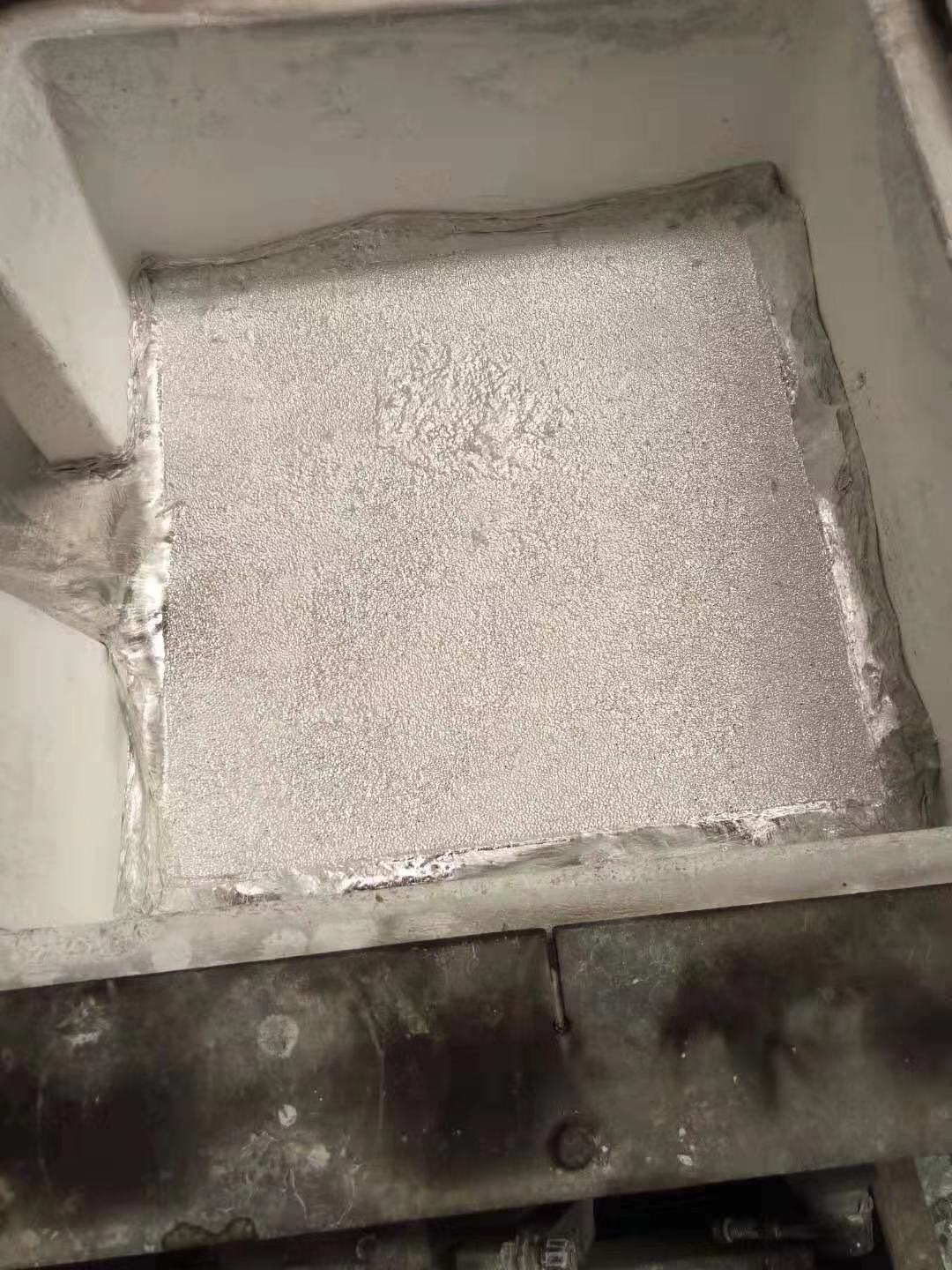

In aluminum melting, the quality of Alu Ceramic Foam Filter is very important, which greatly affects the subsequent processing performance and the quality of the final product.

Therefore, all countries in the world attach great importance to the purification of aluminum melt. There are many reasons for aluminum contamination.

On the one hand, during the smelting process, aluminum is exposed to the atmosphere in the furnace in a molten or semi-molten state, which is easily oxidized and easily reacts with water vapor. Hydrogen is easy to form various forms of non-metallic slag, as well as coarse intermetallic particles.

On the other hand, part of the waste in the composition charge contains some non-aluminum impurities during the recycling process.

Since the waste comes from process waste, waste from various processes in the factory, and waste outside the factory, the route is different, the composition is complicated, and the quality is poor.

These impurities are easy to cause bubbles and inclusions in the slab, which seriously affects the purity of the molten metal, which further affects the processing performance, mechanical properties, corrosion resistance and appearance quality of the product.

Therefore, Alu Ceramic Foam Filter plays a key role in the recycling of aluminum scrap.

Preparation of scrap aluminum

First of all, the primary classification of scrap aluminum is carried out and stacked in grades, such as pure aluminum, wrought aluminum alloy, cast aluminum alloy, and mixed materials.

For waste aluminum products, it should be disassembled to remove the steel and other non-ferrous metal parts connected to the aluminum material, and then wash, crush, magnetic separation, drying and other processes to make waste aluminum.

The liquefaction and separation of scrap aluminum is the development direction of recycling aluminum metal in the future.

It combines the pretreatment of scrap aluminum and re-casting, which not only shortens the process flow, but also avoids air pollution to the greatest extent, and greatly improves the recovery rate of net metal.

The device has a Ceramic Foam Filters For Casting that allows gas particles to pass through. In the liquefied layer, aluminum precipitates at the bottom, and organic matter such as paint attached to the waste aluminum is decomposed into gas, tar and solid charcoal at 450 ℃ or more.

Then complete combustion through the oxidation device inside the separator. The waste is stirred by a rotating drum, mixed with the dissolved liquid in the bin, and impurities such as sand and gravel are separated into the sand and gravel separation zone, and the dissolved water carried out by the waste is returned to the liquefaction bin through the recovery propeller.

According to the preparation and quality status of scrap aluminum materials, and in accordance with the technical requirements of recycled products, select and match and calculate the amount of various materials.

Ingredients should consider the degree of metal oxidation burning loss. The oxidation burning loss of silicon and magnesium is larger than that of other alloying elements. The burning loss rate of various alloying elements should be determined in advance through experiments.

The physical specifications and surface cleanliness of scrap aluminum will directly affect the quality of recycled products and the actual metal recovery rate.

For waste aluminum that is not clean from oil removal, up to 20% of the effective ingredients will enter the slag. Recycled wrought aluminum alloys. Wrought aluminum alloys that can be produced from scrap aluminum alloys include 3003, 3105, 3004, 3005, 5050, etc., of which 3105 alloy is mainly produced.

In order to ensure that the chemical composition of the alloy material meets the technical requirements and pressure processing process requirements, a part of primary aluminum ingots should be added when necessary.

Only a small part of recycled cast aluminum alloy scrap aluminum is recycled into deformed aluminum alloy, and about 1/4 is regenerated into deoxidizer for steelmaking, most of which are used for recycled cast aluminum alloy.

Only a small part of scrap aluminum is recycled into wrought aluminum alloy. The die-cast aluminum alloy A380, ADC10, etc., which are widely used in the United States, Japan and other countries, are basically recycled from scrap aluminum.

The main equipment for secondary aluminum generally uses a dedicated static furnace with oil or gas.

Dubai Aluminium recommend Alu Ceramic Foam Filter manufacture Adtech to UAE Aluminium Company.