Degassing Aluminum Alloys

The purpose of degassing aluminum alloys is to remove aluminum melt containing a certain amount of hydrogen and other residues (alkali metals, slag inclusions), which can be removed by degassing equipment.

The process principle of degassing aluminum alloys is the flotation principle:

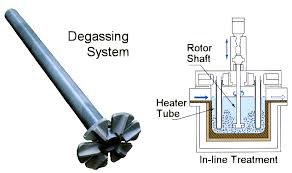

The process gas (inert gas or a mixture of inert gas and chlorine) is sprayed into the melt through the rotor and broken into evenly dispersed tiny bubbles by the rotor.

These tiny bubbles rise to the surface of the melt. During the rising process of the bubbles, the following tasks are completed:

1 Hydrogen is absorbed and eliminated by the bubbles.

2 Alkali metals are eliminated by chemical reaction with chlorine (forming chlorides);

3 Inclusions are captured by bubbles and rise to the surface of the melt to form slag.

The aluminum melt flows into the degassing box and stays in the refractory lining. The box is equipped with a heater to keep the aluminum melt in a molten state.

After the inert gas is sprayed by the rotating rotor, it is broken into countless small bubbles by the high-speed rotating rotor. These small bubbles diffuse and rise in the aluminum liquid, thereby removing hydrogen.

During the rising process of small bubbles, due to the effect of surface tension, part of the inclusions are brought out of the aluminum liquid to the liquid surface, forming slag, thereby removing the inclusions in the aluminum liquid; at the same time, the stirring action of the rotor makes the alloy composition in the aluminum liquid more uniform.

Degassing Aluminum Alloys

A type of degassing equipment – double rotor degasser:

The double rotor degasser is designed for online degassing of aluminum melt with large flow, high gas content, and more inclusions.

Equipped with two degassing rotors that can control the gas flow and speed separately. Special degassing equipment is required, and the double rotor design can provide more powerful stirring and degassing capabilities.

The double rotor degasser is directly connected to the launder system and is equipped with a special slag outlet. The insulation cover and degassing rotor can be raised and lowered by electric lifting, which is convenient for replacing rotor parts. The good insulation design can provide 24-hour uninterrupted online degassing.

Note:

* For critical castings, do not cast on rainy days or high-humidity days, because the castings will have more pores.

*Degassing sheets should be used immediately before pouring to prevent reabsorption of hydrogen after degassing.