The technical concept of Cartridge filtration is based on the principle of heat exchange: that is, to provide the largest possible contact area in the smallest possible space to form a very high filter medium surface.

Tubular/Cartridge filter design principle:

Tubular/Cartridge filter equipment

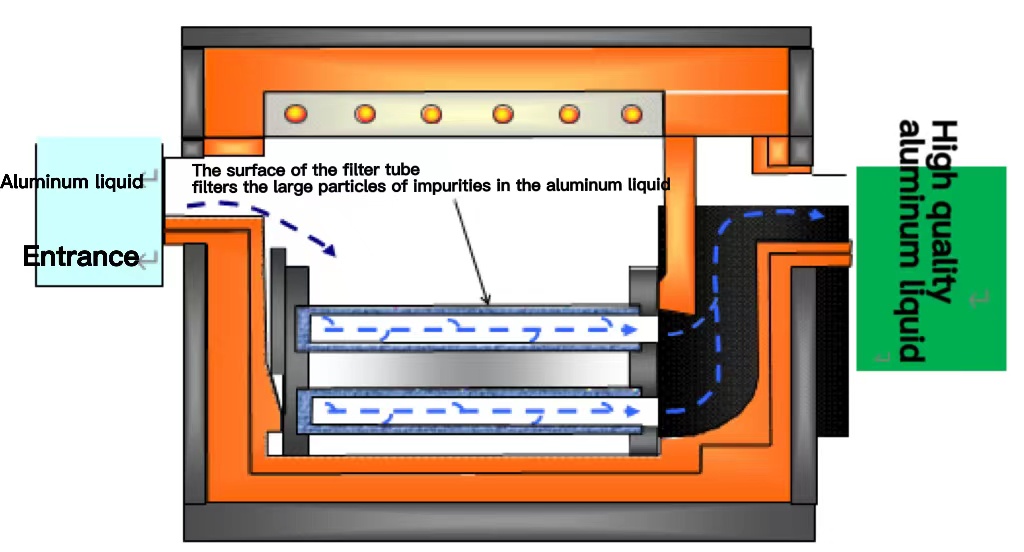

Working principle of Tubular/Cartridge filter

The technical concept of tubular/Cartridge Filtration is based on the principle of heat exchange: that is, to provide the largest possible contact area in the smallest possible space to form a very high filter medium surface. In terms of molten metal filtration capacity, the higher contact surface provided by the tubular filter enables the application of finer filter media at a specific casting flow rate, which greatly improves the filtration efficiency compared to other filtration devices(deep bed filter, plate filter). The Tubular group with the highest filtration level can theoretically remove all the pure aluminum water with impurity particles larger than 5μm.

Theoretical flow calculation of Tubular/Cartridge filter:

Tubular filter equipment

Cartridge filter flow rate (m³/h) = number of Tubular groups * Tubular flow rate * 60 * Number of Tubular groups

(Note: The Tubular flow rate is selected according to the filter accuracy of the selected Tubular group.)

Composition of Tubular/Cartridge filter

The lining of Tubular filter equipment

Tubular/Cartridge filter components

Cartridge filter has 7 major components:

1 Box body: mainly composed of an inner lining, an insulation layer (fiber paper, nano board, calcium silicate board, insulation filling material, and sealing material), and a shell; which mainly contains aluminum liquid and filter medium.

2. Box cover: It is mainly composed of box cover material, an insulation layer (fiber paper, fiber blanket, aluminum foil cloth), anchor nails, and PTFE combined sealing ring; it mainly supports heating components and compressed air ducts, and at the same time reduces the temperature loss of aluminum liquid.

3 Heating components: mainly composed of silicon carbide rods, silicon carbide rod pad Tubular, furnace gas thermocouples, aluminum liquid thermocouples, etc.; mainly to bake the cabinet and ensure that the temperature of the aluminum liquid in the cabinet meets the production process requirements.

4 Tubular group components: mainly Tubular group, wedge block, Cartridge group hoisting tool, and Cartridge filter group installation tool.

5 Electric control cabinet: mainly composed of a touch screen, PLC, power regulator, etc.; it mainly controls the heating power of the heating component according to the requirements of the Tubular/Cartridge filter oven and the production process curve.