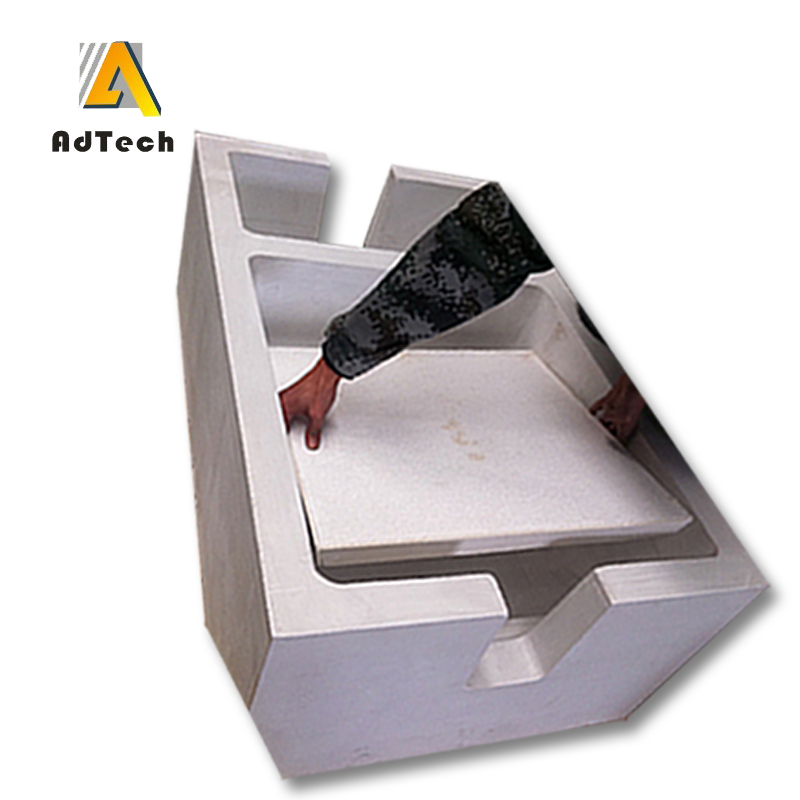

Italy Aluminium Ceramic Filter Foundry to remove the inclusions generated between the refining system and the hot top casting platform.

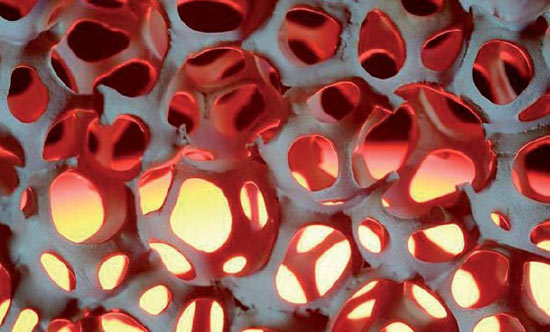

The ability of the ceramic foam filter to capture these inclusions is critical to maintaining a clean ingot during the metal solidification process.

Therefore, the quality and productivity of downstream operations such as forging, extrusion and rolling are guaranteed.

Cast ceramic foam filters-these filters are only used for aluminum castings.

Currently, the market’s leading suppliers offer various sizes and thicknesses.

You must choose the right one according to your requirements.

If your requirements are not suitable for common sizes, you can order custom sizes.

In order to avoid re-oxidation of molten aluminum during casting, pressureless casting technology can be used.

It increases the productivity of the manufacturer while preparing the filter for the next large shipment.

According to Italy Aluminium, purchasing Ceramic Filter Foundry through sales@adtechamm.com can solve the following problems.

Avoid the presence of inclusions. Make aluminum products more corrosion resistant and better appearance.

Avoid pinhole products, looseness, cracks and other defects.

Therefore, Italy Aluminium Ceramic Filter Foundry is the key process of Italy Aluminium aluminum and aluminum smelting.

Common filtering methods for molten aluminum In the modern aluminum melt purification process, the Ceramic Filter For Foundry is close to the end of the last casting purification process.