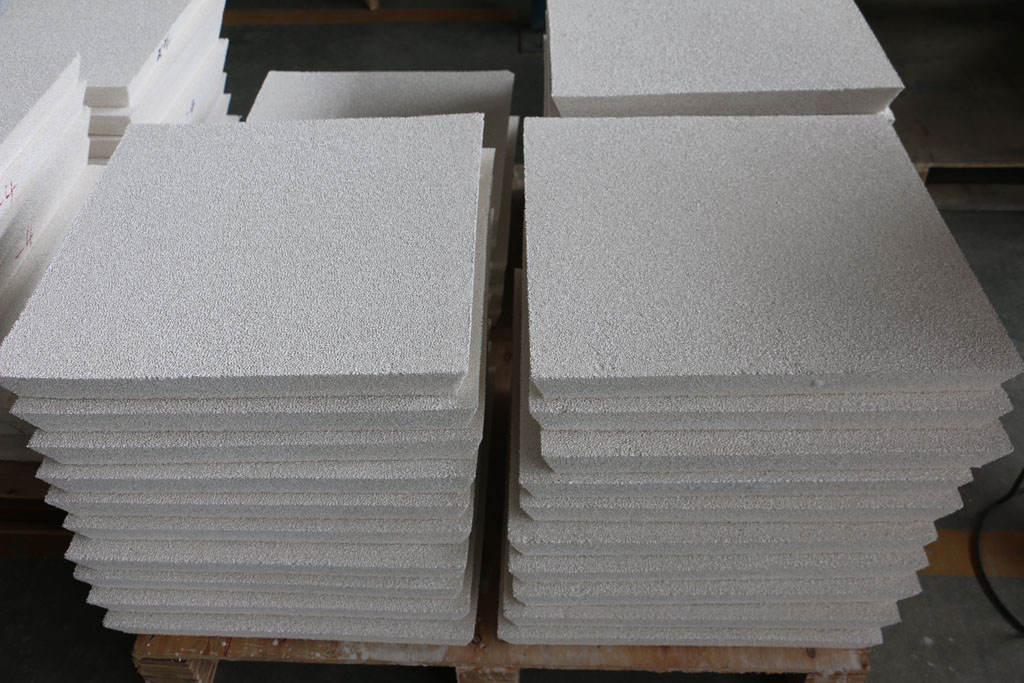

Filtering of Molten Aluminum is mainly used in the purification process of aluminum and aluminum alloy production.

As the quality requirements for aluminum products become higher and higher, the application of ceramic filter plates will become more and more extensive.

The ceramic filter plate of our company employs domestic research talents and adopts the formula and technology of many foreign companies.

It is carefully developed by introducing foreign production equipment and some raw materials. Its performance reaches or exceeds the level of similar foreign products.

1. Product use

It can effectively eradicate large inclusions in molten aluminum.

It can remove small inclusions of a few microns in size in the aluminum liquid that the conventional technology can’t do.

Through adsorption, the content of harmful elements in molten aluminum (Na.k) can be removed.

2. Product specifications

Ceramic foam filter Dimension

660x660x50(26 inch)

584x584x50(23 inch)

508x508x50(20 inch)

432x432x50(17 inch)

381x381x50(15 inch)

305x305x50(12 inch)

228x228x50(9 inch)

178x178x50(7 inch)

Ceramic foam filter Pore Size (PPI): 10/20/30/40/50/60

30ppi 40ppi Foundry Filter is the most commonly used ceramic foam filter in the aluminum casting industry.

Ordinary aluminum casting usually uses 10-40ppi ceramic filter plates.

Aviation and high-quality aluminum materials usually use 30-60ppi ceramic filter plates.

The ceramic foam filter has the characteristics of large filtering area, good thermal shock stability, high chemical stability, good resistance to metal erosion and good filtering efficiency. Therefore, it is used as a new type of high-efficiency filter in the aluminum melt filtration and purification technology. The device has received people’s attention.

In fact, there are many types of Filtering of Molten Aluminum. From a macro point of view, it is mainly divided into open-cell (reticulated) ceramic materials and closed-cell ceramic materials. The key criterion for determining whether a foam ceramic is open-cell or closed-cell is Does it have solid walls?

That is to say, if each pore of the ceramic foam is connected, it is an open-pore ceramic foam, and if it is not connected, it is a closed-cell ceramic foam.

From a microscopic point of view, foam ceramics can be divided into macroporous ceramic materials, microporous ceramic materials and mesoporous ceramic materials.