Buy Foundry Ceramic Filters which uses a three-dimensional network structure and an organic foam sponge connected to the pores as a carrier, invading it into a special ceramic slurry with thixotropic properties.

It adopts a special roll extrusion process to uniformly apply the ceramic slurry to the skeleton of the carrier.

Foundry Ceramic Filters are dried and solidified and then fired at a high temperature.

Foundry Ceramic Filters was using for Aluminum Alloys Since the first research in 1978, foam ceramic filtration technology has developed rapidly.

Foundry Ceramic Filters use polyurethane foam as a carrier, immersing it in a coating made of ceramic powder, binder, sintering aid, suspending agent, etc., and then extruding excess coating to uniformly apply the ceramic coating to the carrier.

The skeleton becomes a green body, and the green body is dried and fired at a high temperature.

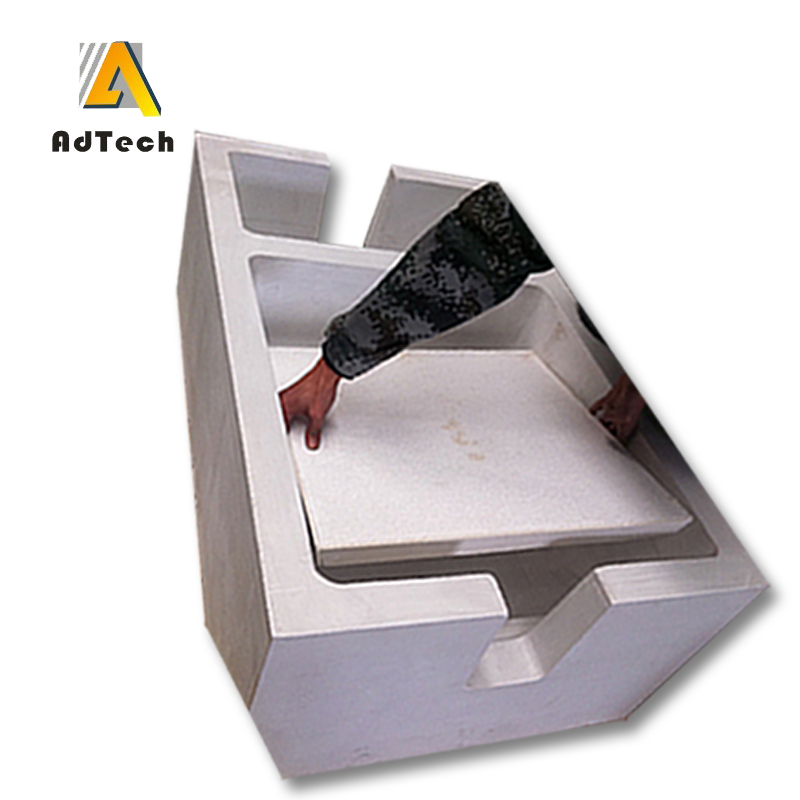

Ceramic Foam Filter can effectively remove large inclusions in molten aluminium and adsorb micron-sized fine inclusion particles to improve surface quality, improve product performance, improve microstructure and improve yield.

Buy Foundry Ceramic Filters and widely used in the production fields of aluminum profiles, aluminum foils, and aluminum alloys.

The Points of Manufacture Porous Alumina Ceramic Foam Filter

Structural characterization of specific reactions in pore size, pore distribution, pore shape and porosity;