Aluminum Liquid Degasser Principle of aluminum liquid degasser: Dissolved hydrogen will move from high concentration areas in the melt (in the melt) to low concentration areas (in the inert gas). Hydrogen gas disperses in molten metal as it would if it were released in any confined space. It will maintain a constant concentration throughout the […]

Ceramic Foam Filters for casting Ceramic Foam Filters for casting are a new type of filter with low density, high porosity, and a three-dimensional network framework structure. It is widely used in the aluminum processing industry to filter molten aluminum, thereby improving the quality of the aluminum. Ceramic Foam Filters for casting Function: The […]

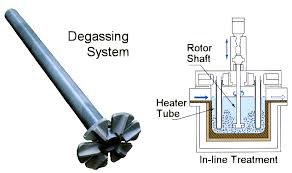

Degassing Aluminum The degassing unit is a special necessary purification equipment for the non-ferrous metal casting industry. The alias is called: degassing unit, aluminum degassing unit, aluminum degassing equipment. Degassing principle: The rotary degasser breaks up large bubbles of inert gas into small bubbles by rotating at a high speed. The rotor sprays the inert […]

Molten Metal Filtration Reasons for Molten Metal Filtration: Solid impurities often found in molten aluminum can damage the final cast metal product. These entrained solid impurities usually come from three aspects: *The floating oxide layer on the surface of the molten aluminum draws aluminum oxide particles into the flow. *The flowing aluminum stream erodes and […]

Standard use and recycling of ceramic foam filters Standardized use of ceramic foam filters in melting and casting workshops. Aluminum alloy smelting uses solvent refining treatment in the furnace and aluminum ceramic foam filters outside the furnace to remove non-metallic slag inclusions in aluminum alloy melts, which has long been an important means of purifying aluminum liquid. […]

1 Introduction During the extrusion production process of aluminum alloy profiles, inclusions are sometimes found on the surface of aluminum profiles. Slag inclusions in aluminum casting rods related to melting and casting mainly include ceramic slag inclusions in filter plates, talcum powder slag inclusions, and high-temperature material slag inclusions in casting trays. Among these casting […]

Improved ceramic foam filter quality As the market demands higher and higher quality ceramic foam filters, to adapt to the market requirements, Adtech pays close attention to production process management in terms of product quality improvement and improved ceramic foam filter quality so that improves the market competitiveness of our products. The company invested to purchase the interior […]

Introduction In the field of mechanical transmission, the worm gear assembly process is a common transmission method. It has the advantages of a large transmission ratio, high transmission precision, and compact structure, and is widely used in various industrial fields. This article will introduce in detail the assembly process steps of worm gears and precautions, […]

With the increasing demand from domestic and foreign customers for our company’s ceramic filter plate products, the current cutting accuracy of the filter board foam body cannot meet customer needs (the original cutting diameter accuracy of the porous ceramic filter was+1mm, -2mm, and the current accuracy has been increased to ± 1mm). To improve product quality, […]

1. Background The briquetting is used in the casting and rolling production line. When in use, the briquetting is placed on top of the porous ceramic filter to prevent the alumina ceramic foam filter from floating during the casting and rolling process. The general service life is 3-6 months; the product needs to have sufficient density and […]